- Hydraulics - Pneumatics

- Pump

- Turbine pump

- Gruppo Aturia SpA

- Products

- Catalogs

- News & Trends

- Exhibitions

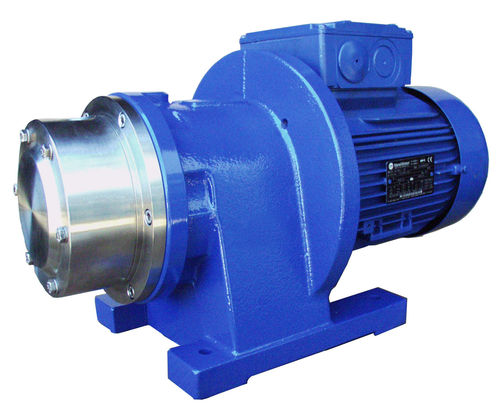

Turbine pump 1/2"÷1" | STMwatermagnetic-drivenormal priming

Add to favorites

Compare this product

Characteristics

- Technology

- turbine

- Fluid

- water

- Operation

- magnetic-drive

- Priming

- normal priming

- Domain

- industrial

- Flow

10 m³/h

(353.14667 ft³/h)- Pressure

16 bar

(232.06 psi)

Description

STM regenerative turbine pumps are ideal for low flow/high head applications. They are able to pump liquids with up to 20% gas content. When the pump's feed is a mixture of two different fluids (gas/liquid or liquid/liquid), the impeller's rotary motion quickly and reliably mixes the fluids, making a static mixer/diffusion pipe unnecessary. The impellers are balanced exactly, free from any residual axial load.

STM pumps have leak-proof magnetic couplings that meet current toxic emissions regulations. The pumps do not have any mechanical seals or packing glands. Thus, there is no scope for process contamination and loss in production time, and costly maintenance is never needed. They are reliable even in hostile working environments. Their dynamic design allows them to be throttled without any by-pass.

The pumps' tough casing and impeller components are made from wrought alloy bars, and they feature a rugged housing for extra safety. The pumps come in Standard and API configurations, and all pumps meet CE-Standards. ATEX Category II rated pumps are also available.

Catalogs

No catalogs are available for this product.

See all of Gruppo Aturia SpA‘s catalogsRelated Searches

- Pump

- Industrial pump

- Pump with electric motor

- Clear water pump

- Centrifugal pump

- Self-priming pump

- Submersible pump

- Top-mounted pump

- Vertical pump

- Process pump

- Service pump

- Single-stage pump

- Distribution pump

- Normal priming pump

- Multi-stage pump

- Semi-submersible pump

- Magnetic-drive pump

- Close-coupled pump

- Firefighting pump

- Turbine pump

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.