- Hydraulics - Pneumatics

- Pump

- Turbine pump

- Gruppo Aturia SpA

- Products

- Catalogs

- News & Trends

- Exhibitions

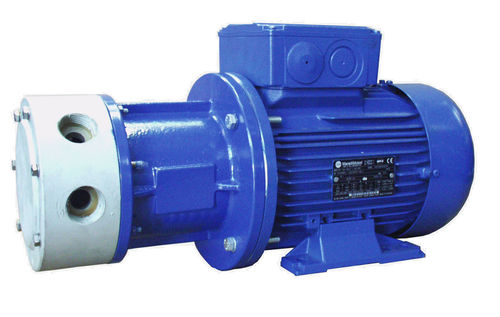

Turbine pump 3/4"÷1"½ | PTMwatermagnetic-drivenormal priming

Add to favorites

Compare this product

Characteristics

- Technology

- turbine

- Fluid

- water

- Operation

- magnetic-drive

- Priming

- normal priming

- Domain

- industrial

- Flow

13 m³/h

(459.09067 ft³/h)- Pressure

10 bar

(145.038 psi)

Description

Using PTM regenerative turbine pumps would dispel the use of oversized centrifugals. Fitted with non-metallic turbine pumps, hence no corrosion and no costly repairs. Is much better than alloy pumps. PTM pumps have remarkable resistance to corrosive materials, so less wear and tear. The flow of the pump not affected by variations in head. As they can throttle to a required duty point, there is no need to bypass the pump.

PTM pumps are encased in PP or PVDF, an exclusive solid machined case. Fitted with an oversized ceramic shaft, silicon carbide as option. The threat of wear due to thrust bearing is eliminated with the help of a self-balancing impeller. Can handle about 20% of the entrained gas. Only low maintenance is required because the impeller is separate. No need for foot valve, foot valve can lift corrosive liquid up to 5 meters. Built according to present CE standards.

Catalogs

No catalogs are available for this product.

See all of Gruppo Aturia SpA‘s catalogsRelated Searches

- Pump

- Industrial pump

- Pump with electric motor

- Clear water pump

- Centrifugal pump

- Self-priming pump

- Submersible pump

- Top-mounted pump

- Vertical pump

- Process pump

- Service pump

- Single-stage pump

- Distribution pump

- Normal priming pump

- Multi-stage pump

- Semi-submersible pump

- Magnetic-drive pump

- Close-coupled pump

- Firefighting pump

- Turbine pump

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.