- Production Machines

- Plastics Processing

- GS Manufacturing

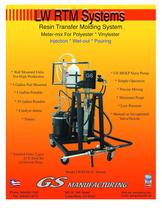

RTM resin transfer molding unit LWRT series

Add to favorites

Compare this product

Characteristics

- Options

- RTM

Description

RTM (Resin Transfer Molding) meter-mix equipment for use in closed molding processes

GS Manufacturings’ line of RTM systems accurately mixes polyester or vinyl ester resins and MEKP (methyl ethyl ketone peroxide) into closed molds containing fiberglass, carbon fiber or other reinforcements. Our RTM systems can be used in light or vacuum assisted processes and are built to order with options such as digital timers, pre determined counters and custom built control boxes.

Examples of industries using our RTM equipment are Marine- boats and personal watercraft, pool and spa, bath ware- tubs and showers, automotive- panels and parts, and aircraft components.

Resin Transfer Molding System

Precise Meter-mix for: Polyester, Vinylester, Injection , Wet-out , Pouring, Simple Operation

Wall mounted units for high production

5 gallon pail mounted

5 gallon portable

55 gallon portable

Catalyst alarm

Timers

GS MEKP slave pump

Simple operation

Precise mixing

Minimum purge

Low pressure

Manual or air-operated valve/nozzle

Standard units: 2 gpm, 25 ft. hose set, air/solvent purge

STANDARD COMPONENTS:

4:1 ARO material pump

S1000-97 MEKP slave

MVA01 manual valve gun

25 foot hose set

Air/solvent purge

Gun rebuild kits

SYSTEM SPECIFICATIONS:

GS MEKP slave pump

Catalyst percentage .75%-3% 25Ft. hose set by volume

Minimum purge

Low pressure

Manual or air-operated valve/nozzle

Air/solvent purge

Standard unit 2 GPM

Options

Additional hose length

Stroke counter

Pre-determined counter

Digital timer

Pneumatic X-Gun dispensing nozzle

Pneumatic X-Gun in place of MVA01 manual valve

VIDEO

Catalogs

LW RTM Systems

1 Pages

Other GS Manufacturing products

Resin Transfer Molding (RTM) / Resin Infusion Systems

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.