- Machine-tools

- Machining Center

- Steel gear hobbing machining

- GSI Ingranaggi Srl

- Products

- Catalogs

- News & Trends

- Exhibitions

Steel gear hobbing machining industrialmedium seriessmall series

Add to favorites

Compare this product

Characteristics

- Treated material

- steel

- Applications

- industrial

- Production method

- large series, medium series, small series

- Other characteristics

- CNC

Description

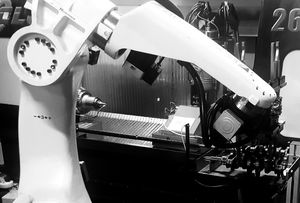

Hobbing system CNC or Pfauter system

In the hobbing system (or Pfauter system) a screw-shaped tool is used, which once directed and rotated, creates the type of toothing required by the design.

In addition to the classic hobbing, GSI can also work using the most innovative Skiving technique, which allows you to finish the tooth profile. In this case, a hard metal hob suitable for the size of the toothing is used, or as a replacement for a grinding wheel when the area to be machined is too small.

Shaper Cutter Toothing or Fellows system

In the Shaper Cutter Toothing (or Fellows system) the tool is circular and has the characteristics of a wheel. It has two different motions: the uniform rotary motion for the advancement and the alternating rectilinear motion for cutting. It is used both for the external dentition, but much more often for the internal dentition.

Tooth size:

Diameter 300 mm, Module 6

Related Searches

- Machining service

- Milling machining

- Metal milling machining

- CNC milling machining

- Precision milling machining

- Turning machining

- Automotive milling machining

- Metal turning machining

- Industrial milling machining

- CNC turning machining

- Small series milling machining

- Medium series milling machining

- Prototyping milling machining

- Automotive turning machining

- Steel milling machining

- Large series milling machining

- Industrial turning machining

- Small series turning machining

- Agriculture milling machining

- Medium series turning machining

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.