- Metrology - Laboratory

- Metrology and Test Equipment

- Temperature test chamber

- Guangdong Bell Experiment Equipment Co., Ltd

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

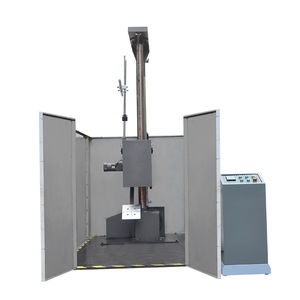

Short circuit test chamber BE-101-1000Astabilitythermal abusefor battery

Add to favorites

Compare this product

Characteristics

- Test type

- short circuit, stability, thermal abuse

- Product applications

- for battery, for automobiles, for materials testing machines

- Configuration

- on casters

- Options and accessories

- PLC-controlled, touchscreen-controlled

- Other characteristics

- stainless steel

- Temperature

Min.: 0 °C

(32 °F)Max.: 200 °C

(392 °F)- Length

1,840 mm

(72.44 in)- Width

1,400 mm

(55.1 in)- Depth

1,300 mm

(51 in)- Power

12,000 W

Description

Thermal abuse test chamber protect for short circuit caused by incorrect operation of the operator and battery electrode, battery positive and negative connection, etc

Description

Thermal Abuse Test Chamber Standards

• IEC 62133

• IEC 62619

• UL 1642

Relevant standards requirement

Single storage cell Safety Test

Heating test steps:

• Charge the battery according to the standard 6.1.3

• Place it intothechamber

–For lithium storage battery,the oven temperature is raised at a rate of 5℃/min to a

temperature of 130℃±2℃,remain this temperature for 30min, then stop heating;

–For metal cyanide nickel battery, the oven temperature is raised at a rate of 5℃/min to

a temperature of 85℃±2℃,remain this temperature for 2h,then stop heating.

• Observe for 1h

Storage Battery Module Safety Test

• Charge the battery module according to the standard 6.1.4

• Place it into thechamber

-For lithium storage battery,the oven temperature is raised at a rate of 5℃/ min to a

temperature of 130℃±2℃,remain this temperature for 30min, then stop heating;

–For metal cyanide nickel battery, the oven temperature is raised at a rate of 5℃/ min to

a temperature of 85℃ ±2 ℃,remain this temperature for 2h,then stop heating.

• Observe for 1h

Technical Parameters:

Control Accuracy: ±0.5℃

Temp. Uniformity: ±2.0℃ ( No load)

Temp. Rising Speed: RT~150℃ (≧5℃/min,liner with load 40kg module)

Temp. overshoot: ≦2.0℃

Control Display Method: PLC Touch screen + remote control, networking,

cell phone APP alarm device, with USB interface, R485 interface can be connected to computer controlling.

Testing Room Dimension: W1000 X D1000 X H1000 mm

Inner chamber Material: SUS304 Stainless Steel (Mirror finished)

Catalogs

Other Guangdong Bell Experiment Equipment Co., Ltd products

Battery Module Test Chambers

Related Searches

- Test machine

- Test cabinet

- Material testing machine

- Automatic test machine

- PC-controllable testing machine

- Temperature test cabinet

- Climatic test chamber

- Vertical test machine

- Humidity test cabinet

- Industrial test machine

- Universal test machine

- Tensile test machine

- Digital testing system

- Laboratory test machine

- Automatic test equipment

- Industrial testing system

- Precision test machine

- Research and development test machine

- Stainless steel test cabinet

- Electromechanical test machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.