- Metrology - Laboratory

- Metrology and Test Equipment

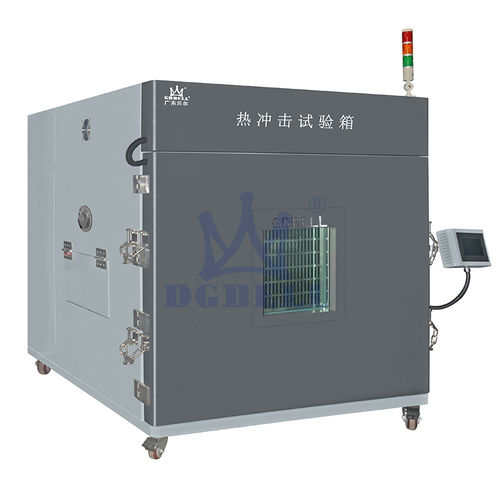

- Temperature testing machine

- Guangdong Bell Experiment Equipment Co., Ltd

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Temperature testing machine BE-101thermal shockPC-controllablebattery

Add to favorites

Compare this product

Characteristics

- Test type

- temperature, thermal shock

- Operating mode

- PC-controllable

- Test material

- battery

- Other characteristics

- high-temperature

Description

Temperature Thermal Shock Testing machine for the energy sector

Thermal Shock Test Chamber Application

DGBELL's Thermal Shock Chamber is developed to meet the greater demands for highly accelerated stress tests (HAST) of electrical and electronic components. The specimen transfer directly between the hot and cold zone to achieve rapid product temperature change for thermal shock, also known as the Environment Stress Screen test. It is widely used as a lab test and product manufacturer to test its product qualification and reliability.

Single Battery Safety Test

The heating test is carried out according to the following steps.

a. Single battery is charged according to 7.1.1 method

b. Put the single battery into the temperature chamber

1. For lithium-ion battery, the temperature box is increased from room temperature to 130ºC±2ºC at a rate of 5ºC/min and kept at this temperature for 30min and then stop heating

2. For nickel metal cyanide battery, the temperature chamber is increased from room temperature to 85ºC±2ºC at a rate of 5ºC/min and the heating is stopped after keeping this temperature for 2 hour.

c.Observe 1 hour

Other Guangdong Bell Experiment Equipment Co., Ltd products

Hot Products

Related Searches

- Test machine

- Test cabinet

- Material testing machine

- Temperature test cabinet

- Automatic test machine

- PC-controllable testing machine

- Climatic test chamber

- Humidity test cabinet

- Vertical test machine

- Industrial test machine

- Universal test machine

- Tensile test machine

- Digital testing system

- Automatic test equipment

- Laboratory test machine

- Industrial testing system

- Precision test machine

- Environmental test cabinet

- Research and development test machine

- Electromechanical test machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.