- Metrology - Laboratory

- Metrology and Test Equipment

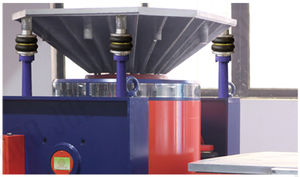

- Impact test bench

- Guangdong Jian Qiao Testing Equipment Co., Ltd.

Impact test bench JQJ-50for the automotive industryfor civil and military aviationfor the aerospace industry

Add to favorites

Compare this product

Characteristics

- Test type

- impact

- Sector

- for the automotive industry, for civil and military aviation, for the aerospace industry, for the electronics industry

- Technology

- mechanical

Description

The mechanical impact test bench simulation equipment and components are mainly used in the process of transportation and impact, and through the shock wave in the instantaneous instantaneous energy exchange, the ability of the product to withstand external impact environment is analyzed. The purpose of the test is to understand its machinery. Structural weaknesses and degradation of specific functions are a kind of destructive experiment, which helps to understand the structural strength and appearance of products, such as impact resistance and drop. If the product is destructively tested, it can effectively predict the reliability of the product. Degree and monitoring of the consistency of production line product manufacturing. When the test is performed, the test piece is usually fixed on the fixture or the impact test platform, and the impact waveform is half-sine wave which is often used in the specification.

The mechanical impact test bench test piece is fixed on the impact table surface, and the collision table surface and the lower waveform generating pad collide continuously, and a continuous impact half sine wave is generated on the table surface. This long-term continuous collision can accurately describe the degree of damage to the test piece subjected to continuous impact and the fatigue degree of the test piece. Different test requirements, change the duration of the impact acceleration by changing the waveform generation pad, change the free fall height to change the magnitude of the impact peak acceleration, set the number of consecutive collisions, and investigate the degree of fatigue damage of the test piece.

Catalogs

Impact test bench JQJ-50

8 Pages

Other Guangdong Jian Qiao Testing Equipment Co., Ltd. products

Electrodynamic shaker

Related Searches

- Test machine

- Test cabinet

- Test stand

- Material testing machine

- Automatic test machine

- PC-controllable testing machine

- Temperature test cabinet

- Compression test machine

- Climatic test chamber

- Vertical test machine

- Automatic test stand

- Humidity test cabinet

- Industrial test machine

- Stainless steel test cabinet

- Electromechanical test machine

- Environmental test cabinet

- Hydraulic test machine

- Automobile test cabinet

- Test chamber with window

- Vehicle test chamber

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.