- Metrology - Laboratory

- Metrology and Test Equipment

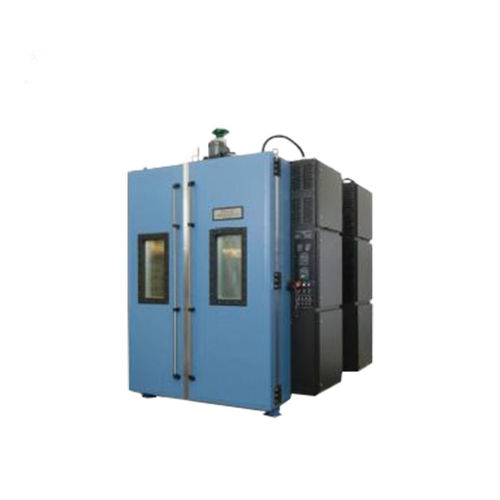

- HASS test chamber

- Guangdong Jian Qiao Testing Equipment Co., Ltd.

HALT test chamber HASSfor automobilesfor materials testing machines

Add to favorites

Compare this product

Characteristics

- Test type

- HALT, HASS

- Product applications

- for automobiles, for materials testing machines

- Configuration

- vertical

- Options and accessories

- with temperature and climatic control

- Other characteristics

- stainless steel

- Capacity

Max.: 1,200 l

(317 gal)Min.: 812 l

(215 gal)- Temperature

Max.: 200 °C

(392 °F)Min.: -100 °C

(-148 °F)

Description

HALT (Highly Accelerated Life Test) - HASS (Highly Accelerated Stress Screening), which is a test method that can improve product reliability and can inspire product defects in a short time. Improve, reduce product development, design, repair costs; improve product reliability and shorten time to market. It is widely used in electronics, communications, aerospace, aviation, military, medical equipment, energy equipment and other fields.

Features

Quickly find out the product process (quickly find defect within 3-5 days)

The manufacturing process grows, accelerating design and manufacturing maturity (after giving incentives and failures, modifying the design and accelerating the maturity of design and manufacturing)

Shorter time to market and faster time to market (short test time)

Increase MTBF (average failure time growth)

Extended warranty

Reduce warranty costs (reduced recycling repair costs);

Early data on product strength (means to improve product strength);

Reduce costs (reduce product development time and cost);

Customers use high reliability products

Catalogs

No catalogs are available for this product.

See all of Guangdong Jian Qiao Testing Equipment Co., Ltd.‘s catalogsRelated Searches

- Test machine

- Test cabinet

- Test stand

- Material testing machine

- Automatic test machine

- Temperature test cabinet

- PC-controllable testing machine

- Compression test machine

- Climatic test chamber

- Vertical test machine

- Humidity test cabinet

- Automatic test stand

- Industrial test machine

- Environmental test cabinet

- Electromechanical test machine

- Stainless steel test cabinet

- Hydraulic test machine

- Automobile test cabinet

- Test chamber with window

- Industrial test bench

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.