- Metrology - Laboratory

- Metrology and Test Equipment

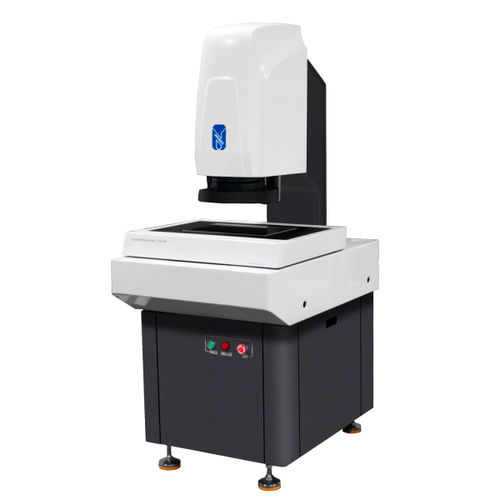

- Shape measuring system

- Guangdong Jinuosh Technology Co.,Ltd

Geometry measuring machine FMV300diametercontourshape

Add to favorites

Compare this product

Characteristics

- Measured physical value

- geometry, diameter, contour, shape, angle, roundness, concentricity, vision processing, distance, position, curve radius, circumference, flaw

- Technology

- video, vision, instant imaging, camera-based, 3D, laser, visual

- Measured material

- bearing, for PCB, parts, shaft, tool, for wafers, bearing, optical lens, for cables, for inside diameter measurements, for countersinking, for ophthalmic lenses, for saw blades, strip

- Applications

- laboratory, for industrial applications, control, for electronics, for the automotive industry, for medical applications, calibration, for production lines, for gears, for component testing, for watchmaking, for LCDs

- Other characteristics

- dimensional, high-precision, automatic, CNC, horizontal, digital readout, non-contact, ultra-high accuracy, high-speed, vertical, white light, high-resolution, multi-sensor, continuous, multi-sensor, geometric, cantilevered, 2-axis

Description

Specification

• XY Axis Moving Range : 230mmx140mm

• Z Axis Moving Range : 200mm

• Camera : 20MP Black and White

FOV

• Wide field of view measurement mode : 300 mm×200 mm

• High-precision measurement mode : 225mm×140mm

• Magnification : Lens 0.7X-4.5X,Monitor magnification :30X-240X

• Max Height of Measured Part : 75mm

• Resolution : 0.1 μm

Measuring accuracy

Wide field of view measurement mode

• Stage fixed(not moving) : ±3.9μm

• Stage Moving : ±(7+0.02L)μm

High-precision measurement mode

• Stage fixed(not moving) : ±2.0μm

• Stage Moving : ±(2.8+0.02L)μm

Repeat accuracy

Wide field of view measurement mode

• Stage fixed(not moving) : ±1.0 μm

• Stage Moving : ±2.0μm

High-precision measurement mode

• Stage fixed(not moving) : ±0.5μm

• Stage Moving : ±1.5μm

• Z-axis Measurement range (not moving) - ±3.5mm

Z-axis measurement accuracy

• Stage fixed(not moving) - ±2μm

• Stage Moving - ±(6.0+L/100)μm

• Max Number of Measurable Positions at One Time - 500

• Max Number of Measurable Parts at One Time - 200pcs

Function

• Automatic Testing : Place and measure with one key, automatically identify measurement positions, automatic testing, automatically determine the result YES or NO

• Arbitrary Placement of Products : Supports arbitrary placement, can search for the measurement target

• Scanning Function : Scan and read the QR code on the inspection report to read the setting file, avoiding program errors

• Data Storage : Measurement results and test date/time/batch number information are automatically saved

• Data Output : Create inspection result reports and statistical reports with one key

VIDEO

Catalogs

No catalogs are available for this product.

See all of Guangdong Jinuosh Technology Co.,Ltd‘s catalogsOther Guangdong Jinuosh Technology Co.,Ltd products

FLASH MEASURING MACHINE

Related Searches

- Measuring machine

- Optical measuring machine

- Automatic measuring machine

- High-precision measuring machine

- Measuring system for industrial applications

- Parts measuring machine

- Distance measuring machine

- Control measuring machine

- Non-contact measuring machine

- Laser measurement system

- Diameter measuring machine

- Video measuring machine

- Geometry measuring machine

- Dimensional measuring machine

- Laboratory measuring machine

- 3D measuring machine

- Measuring system for the automotive industry

- CNC measuring machine

- Electronic measuring machine

- High-speed measuring machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.