- Hydraulics - Pneumatics

- Pipe, Tube and Fitting

- Spray nozzle

- Guangzhou Cleaning Spray Equipment

- Products

- Catalogs

- News & Trends

- Exhibitions

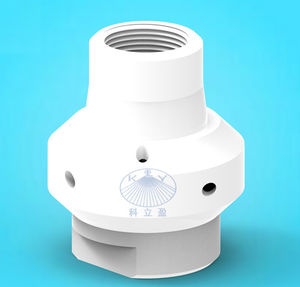

Cleaning nozzle STP-150sprayfor liquidsstainless steel

Add to favorites

Compare this product

Characteristics

- Function

- cleaning, spray

- Fluid

- for liquids

- Material

- stainless steel

- Applications

- for the food industry, for pharmaceutical applications, for tanks, chemical

- Other characteristics

- retractable

Description

When baffles are a nuisance.

Dynamic Retractor CIP systems clean even the remotest corners. Where to attach the spray head? This question arises with nearly every CIP installation. In most cases, spray shadows caused by baffles, such as agitators, manholes, inspection glasses and a host of other muffs complicate the setup of an efficient CIP cleaning. The solution for this is a retractable cleaning systems.

An elegant solution is a so-called retractor using flood cleaners. A pneumatic drive extends the flood cleaner to its place of operation. This in itself is nothing new: technical variations have been known on the market for many years. The KLY retractable tank cleaning nozzle combines this fundamental idea with the modern demands on a CIP cleaning system. Depending on the cleaning head model and the working pressure, flow rates between 1 and 10 m3/h are currently possible. A detergent pressure between 1 and 8 bar can be selected.

Another important component of the retractable tank cleaning nozzle is the hydraulic pipe. Employing the new pipe standard DIN 11866 permitted a considerable reduction of the installation size and thus of the cavity into which the spray head is retracted.

Some important features at a glance:

low wear PEEK body

slide bearing

easy to maintain

drainable

designed for the food Industrie

Application:

STP-150 series retractable rotary nozzle are well suited to pharmaceutical, food and beverage, chemical and other industries. Particularly suitable for pipes and corner,such as spray dryer.

Spray dryer

Fluid bed dryers

Granulator

Pipe

Other Guangzhou Cleaning Spray Equipment products

Tank cleaning nozzle

Related Searches

- Fitting

- Hydraulic fitting

- Screw-in fitting

- Pneumatic fitting

- Stainless steel fitting

- Spray atomizing nozzle

- Liquid atomizing nozzle

- Stainless steel atomizing nozzle

- Male fitting

- Cleaning atomizing nozzle

- Threaded nozzle

- Multi-jet atomizing nozzle

- Air atomizing nozzle

- Brass atomizing nozzle

- Flat spray atomizing nozzle

- Cooling atomizing nozzle

- Plastic nozzle

- Full-cone atomizing nozzle

- Compact fitting

- Chemical nozzle

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.