- Hydraulics - Pneumatics

- Pipe, Tube and Fitting

- Spray nozzle

- Guangzhou Cleaning Spray Equipment

- Products

- Catalogs

- News & Trends

- Exhibitions

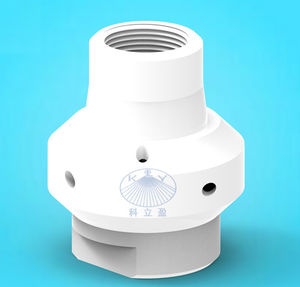

Spray nozzle DG20cleaningfor liquidsstainless steel

Add to favorites

Compare this product

Characteristics

- Function

- spray, cleaning

- Fluid

- for liquids

- Material

- stainless steel

- Applications

- for the food industry, for pharmaceutical applications, for tanks, chemical

- Other characteristics

- rotary, high-impact

Description

Model:DG20 High impact 3D rotary tank cleaner

Material:316L ss

Max. tank diameter: 20m

Operating pressure:5-20Bar

Tempreture range:95°

Installation:Vertically facing downward

Application:

Cleaning and rinsing of large tanks

i.e. chemical industry,drink and food industry.

DG20 tank cleaner for the largest tanks and most difficult applications, this gear driven cleaning nozzle is our most powerful.

Very high cleaning performance already at low pressure

Driven and lubricated by the cleaning fluid

Systematically cleans the entire tank interior(360°)

Robust, low-maintenance stainless steel construction

100% thoroughly clean,every time

Optimized structural design makes water jet with greater impact

Excellent seal design, only 3% leakage of water

Designed with a separate gearbox,uneasy to get clogging

Programmed rotation machines:

The cleaning fluid drives via the turbine an internal gear reducer that keeps the sprayer turning in two planes.

In the course of spraying cycle, the jets sweep the entire inside surface of the tank according to the preprogrammed, model-specific pattern.

This takes a certain amount of time, but these models generate the highest jet pressures (= force of impact) and are therefore ideal for very large tanks and the toughest of cleaning tasks.

The standard machine configuration uses two or four nozzles to blast the tank walls and rinse all surfaces. In operation, the unit has to run for the cycle time between on type 8 and 12 min depending on type and pressure. This ensures full cleaning. For extremely difficult applications the cleaning time might have to be extend.

VIDEO

Other Guangzhou Cleaning Spray Equipment products

Tank cleaning nozzle

Related Searches

- Fitting

- Hydraulic fitting

- Screw-in fitting

- Pneumatic fitting

- Stainless steel fitting

- Spray atomizing nozzle

- Liquid atomizing nozzle

- Stainless steel atomizing nozzle

- Male fitting

- Cleaning atomizing nozzle

- Threaded nozzle

- Multi-jet atomizing nozzle

- Air atomizing nozzle

- Brass atomizing nozzle

- Flat spray atomizing nozzle

- Cooling atomizing nozzle

- Plastic nozzle

- Full-cone atomizing nozzle

- Chemical nozzle

- Atomizing nozzle for the food industry

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.