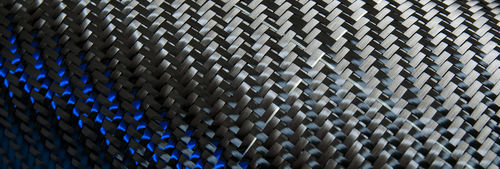

Epoxy prepreg system SE 140 high-performance

Add to favorites

Compare this product

Characteristics

- Resin type

- epoxy

- Other characteristics

- high-performance

Description

¬ Optimised prepreg for compression moulding and autoclave cure

¬ Flow-controlled resin for improved surface finish

¬ Toughened for improved mechanical properties

¬ 20min Cure at 130-135°C (266-275°F)

SE140 is designed for manufacture of complex composite components which are typically manufacture in the automotive, motorsport and sporting goods sectors. The cured resin has a good balance of laminate strength, toughness and environmental performance making it a very versatile product.SE140 is a flow controlled prepreg, which has been optimised for fast cure under high consolidation pressures but can also be cured under vacuum pressure if required. The prepreg resin provides suitable tack to adhere to metal and composite tools but is still easy to reposition at ambient temperatures.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Gurit‘s catalogsRelated Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.