Linear velocity sensor Q-Eye PSCDopplerstainless steel

Add to favorites

Compare this product

Characteristics

- Type of movement

- linear

- Technology

- Doppler

- Other characteristics

- stainless steel

- Frequency

1 MHz

- Temperature range

Max.: 50 °C

(122 °F)Min.: 0 °C

(32 °F)

Description

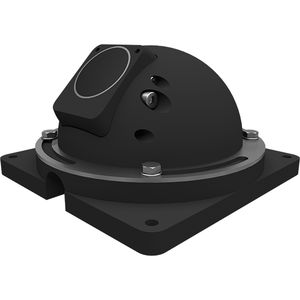

Insertion sensor uses advanced Pulse-Doppler technology. The velocity profile of the entire cross-section is captured in up to 18 measurement cells. The insertion sensor is used when the pipe is only accessible from the outside. This sensor is for use in full pipes or in partially filled pipes in combination with an integrated pressure transducer. The installation is carried out by means of a 1.5” ball valve into existing pipework.

The insertion sensor is mounted flush with the inner pipe wall, allowing pipes to be cleaned without removal of the sensor. Additionally, the flow profile is not altered by the sensor itself. Should the sensor ever need to be removed, it can be done under process conditions thanks to the integrated ball valve.

TECHNICAL SPECIFICATIONS

Sensor:

Velocity sensor for partially and fully filled pipes incl. ball valve

Optional with integrated pressure transducer for level measurement

Frequency: 1 MHz

Range:

‒ Velocity: ± 5.0 m/s

‒ Level (pressure transducer): 0…0.2 bar or 0…10 bar

Uncertainty velocity:

± 0.03 m/s from -1.5 m/s to +1.5 m/s

± 2 % of reading from -5.0 to -1.5 m/s and +1.5 to +5.0 m/s

Uncertainty pressure transducer:

‒ Linearity: 0.5 % FS (0.2 bar) or 0.25 % FS (10 bar)

‒ Error band 0 to 50 °C: max. 1.5 % FS (0.2 bar) or 0.5 % FS (10 bar)

Cable length: 10 m incl. (max. 80 m)

Material: Stainless steel 1.4301 (AISI 304)

Dimensions Diameter: 38 mm (1.5”)

Catalogs

No catalogs are available for this product.

See all of GWF‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.