- Industrial machines and equipment

- Heat Exchanger and Refrigeration

- Oil cooler

- H.Stars (Guangzhou) Refrigerating Equipment Group Ltd.

Water chiller 40STDoillow-temperaturescrew compressor

Add to favorites

Compare this product

Characteristics

- Material

- water, oil

- Other characteristics

- low-temperature, screw compressor, screw

Description

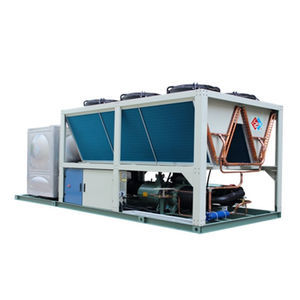

Flooded Type Screw Low Temperature Chiller Unit

40STD series Flooded type screw low-temperature chiller adopts high-efficiency dual-screw compressor, self-developed and

manufactured high-efficiency Flooded type evaporator, R22 and R134a refrigerant. Heat recovery can be configured based on customer thermal needs. The unit has 39 standard specifications.

Flooded Type Screw Low Temperature Chiller Unit

Profile

40STD series Flooded type low-temperature chiller adopts high-efficiency twin-screw compressor, self-developed and manufactured high-efficiency Flooded type evaporator, R22 and R134a refrigerant. Heat recovery can be configured based on customer thermal needs. The unit has 39 standard specifications.

Brand: H'Stars

Unit Performance and Advantage

(1) It adopts Flooded type low temperature compressor, which is stable in operation, low in noise and long in service life.

(2) Using an independently developed high-efficiency flooded evaporator, the evaporation temperature can reach -2 °C, and the refrigeration effect is increased by 15%.

(3) High-efficiency oil separator using impact and interception oil separation technology. There are thousands of grades.

(4) Adopting evaporator ejector oil return technology, no moving parts, no energy consumption, stable and energy saving.

(5) The use of a well-known brand electronic expansion valve + orifice throttle device.

(6) Optional microcomputer control, PLC control, and expandable network functions, providing remote monitoring and after-sales service.

(7) Optional independent research and development patent collector to obtain free hot water.

Catalogs

Other H.Stars (Guangzhou) Refrigerating Equipment Group Ltd. products

INDUSTRIAL CHILLER

Related Searches

- Chiller

- Liquid chiller

- Heat exchanger unit

- Water chiller

- Air chiller

- Liquid/liquid heat exchanger

- Industrial chiller

- Compact chiller

- Tubular heat exchanger

- Stainless steel chiller

- Stainless steel heat exchanger unit

- Gas/liquid heat exchanger unit

- Blast chiller for the food industry

- Air-cooled recirculation chiller

- Industrial heat exchanger unit

- Oil chiller

- Laboratory recirculation chiller

- Compact heat exchanger unit

- Process water cooler

- Copper heat exchanger

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.