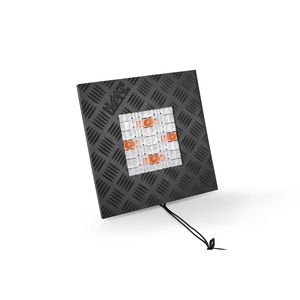

Safety for doors locking device HST

Add to favorites

Compare this product

Characteristics

- Options

- safety for doors

Description

Safety of machinery

Hazardous machines and systems are frequently equipped with safety elements (safety doors) with a locking mechanism to protect the operator. Their function is:

a) to prevent hazardous machine functions if the safety door is not closed and locked,

b) to keep the safety door closed and locked until the risk of injury has passed.

A general example: A machine has one or more maintenance openings (part-body access) or is accessible through one or more doors (full-body access). On the one hand, it has to be secured that the machine isswitched off, before one of these openings or doors can be opened.

...On the other hand, the machine must only be re-set into operation, if all openings and doors are closed, and nobody is present inside the machine.

Benefits for user

Such guard locking devices are for instance key-operated mechanical interlocks, also called trapped-key systems. They are based on the easy-to-understand premise that a key cannot be in two places at the same time - it can for instance be inserted in a switch OR be used for opening a guard. Another safety-relevant feature is that a key can only become free in a safe condition, when there are no hazards - a switch is turned off, a guard interlock is closed and locked.

The big advantage of the system is the fact that a certain sequence of steps can be pre-determined when designing the system. It is not possible to deviate from this sequence - thus a high degree of integrity is achieved. So virtually any hazard can be eliminated. The system consists of a central electrical part (for instance in the control panel) and mechanical units at the guards.

Exhibitions

Meet this supplier at the following exhibition(s):

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.