Usage:

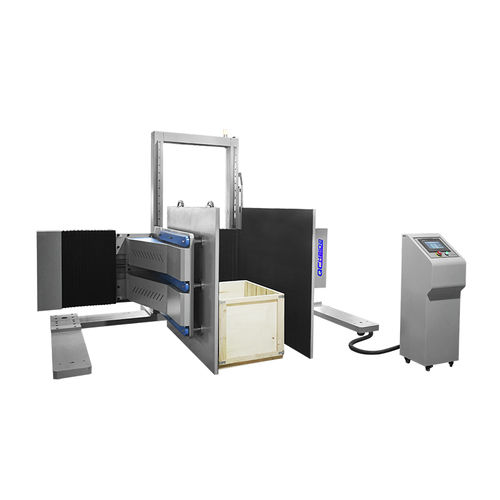

clamping force tester simulates the process the schnabel car discharge the package, during this process, the clamping force of the both boards will affect the package and cargo. And this test is to evaluate the resistance property of the package toward this clamping force.

Specimen shape Parallelepiped transport package

Max. Specimen weight: 500kg

Clamping board size: H*D 48*48inch

Clamping board adjustable height: 0~500mm

Elevation speed: 10~300mm/min optional

Clamping board expansion width: 200~2000mm

Baseboard dimension: W*D 1500*1500mm

Device width: Less than 2.5m

Test standards:

ASTM D6055-96 METHOD, ISTA Packaging Test EHP Cold, LTP-2001 Clamping test,

GB/T 4857.4-2008 Basic Experiment of Packaging and Transporting Packages,

ISTA (International Safety Transit Association) 1A Packaging Performance of Independent Packaging Products That is No Heavier Than 1501b (68kg),

ASTM Standard D 4169 Standard Operating Specification for Shipping Containers and System Protection Performance test,

ASTM Standard D 6055 Standard Test Method for Compositional Load and Mechanized Transport of Large-scale Shipping Containers or Crates,

ASTM Standard D 6179 Standard Test Method for Compositional Load and Rash Transport of Large-scale Shipping Containers or Crates,

ASTM Standard D 999, Standard Test Method for Shock Test of Shipping Containers,

ASTM Standard D 5445 Geographical Symbols for Standard Operational Actions in Cargo Transport.