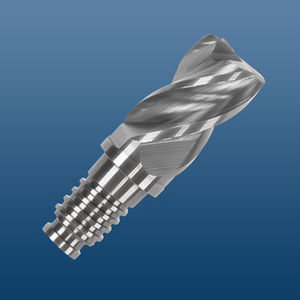

Solid carbide milling cutter HF seriescuttingmachine tool

Add to favorites

Compare this product

Characteristics

- Construction

- solid carbide

- Other characteristics

- cutting, machine tool

- Diameter

6 mm, 8 mm, 10 mm

(0.24 in, 0.31 in, 0.39 in)- Length

58 mm, 64 mm, 73 mm

(2.28 in, 2.52 in, 2.87 in)

Description

The solid carbide end mills of the HAIMER MILL HF Series have been developed for the highest feed rate speeds in steel applications. In addition, the tools can be used for applications in stainless steel, cast iron, aluminium alloys, titanium alloys and hardened steel.

Due to the special face geometry, maximum feed rates can be achieved with simultaneous dissipation of the axial forces in the direction of the spindle axis, which ensures optimum load distribution.

Air or coolant can be fed through central cooling bores of the cutting tool. This prevents chip accumulation, cools the cutting edge reliably and thus, increases the tool life.

Because of a very high runout accuracy of < 5 μm and a balance quality of less than 1 gmm, the milling cutters are also ideally suited for highest speeds and therefore protect your machine tool by low vibration inclination.

Characteristics:

Shank tolerance: h5

Neck for higher cutting depth

Runout < 5 μm

Inner cooling

Catalogs

No catalogs are available for this product.

See all of HAIMER GmbH‘s catalogsRelated Searches

- Milling tool

- Solid milling tool

- Steel milling tool

- Clamping milling cutter

- Metal milling tool

- Cutting milling tool

- Hemispherical milling cutter

- Solid carbide milling tool

- Roughing milling tool

- Corner radius milling tool

- Aluminum milling tool

- Diamond milling tool

- Weldon milling cutter

- Machine tool milling cutter

- Superfinishing milling cutter

- Copying milling cutter

- Center cutting milling cutter

- PVD milling cutter

- Screw-in milling tool

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.