- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

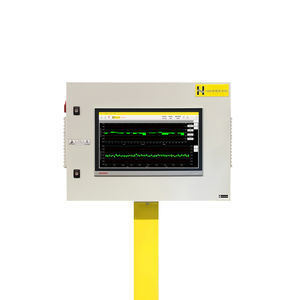

Machine vision vision system Edge-Vision-4.0monitoringinspectiondetection

Add to favorites

Compare this product

Characteristics

- Function

- monitoring, detection, inspection, quality control, machine vision

- Applications

- for machines

- Domain

- industrial, for the steel industry

- Options

- camera-based, in-line, AI

Description

Edge-Vision-4.0 is a high-resolution machine vision system for surface inspection. It uses advanced machine-vision technology to capture and analyze detailed images of products and processes, helping industries detect and address defects in materials. The system is integrated into rugged steel CURTAIN frames, making it durable and reliable for continuous and batch processes.

How Does Edge-Vision-4.0 Work?

Edge-Vision-4.0 operates using camera-based technology and can also employ line lasers and specialized color sensors. It is mainly used in continuous roll-to-roll processes such as nonwovens, textile coatings, and plastics extrusion, but can also be applied in batch processes or bulk processing/production (food industry, sorting applications, wood pulp industry…).

What can we detect?

Black Spot Detection

Identifies black spots in extruded films and sheets.

Stripe Detection

Detects length-direction stripes from die contamination in extruded sheets.

Foreign Object Detection

Finds foreign objects in non-woven materials

Anomaly Detection

Identifies holes, stains, stitching errors, and printing anomalies in textiles

Defect Detection

Detects fractures and defects in battery film coatings

Color and Glossiness Detection

Quantifies color variations and identifies surface glossiness variations or transparency issues.

As AI is increasingly on the rise, we developed an AI-enabled feature. Based on a dataset of images, pre-classified by the customer, we use artificial intelligence to execute a learning process offline and build a powerful neural network for use during in-line quality control.

VIDEO

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.