- Production Machines

- Other Manufacturing Equipment

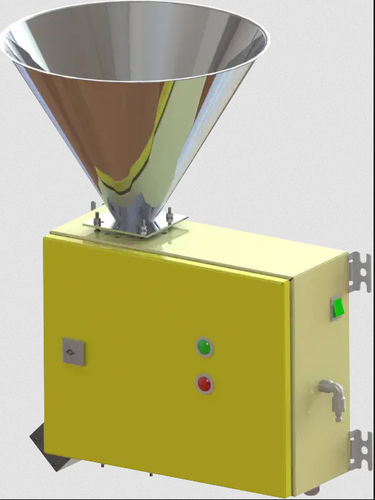

- Separator screen

- HAMOS GmbH, Recycling- und Separationstechnik

Separator screen HS

Add to favorites

Compare this product

Description

hamos HS electronic all-metal separators are used for the detection and fully automatic removal of isolated metallic contaminants from free-falling, free-flowing bulk materials. Not only ferrous metals are detected, but also all non-ferrous metals, such as aluminum, copper, brass, etc. The result is a practically metal-free bulk material. The result is a practically metal-free product. hamos HS all-metal separators protect products, machines and tools safely, reliably and cost-effectively from damage caused by metal contamination.

Operating principle

The free-flowing bulk material falls in free fall through the shaft of the hamos HS all-metal separator.

A high-frequency alternating field is generated inside an electromagnetic coil, which is influenced by metal particles flying through it. Each metal particle, when it falls through the coil opening, triggers a pulse. In this way, any metal particles above a certain size that may be contained are detected electronically by the metal detection coil and separated and ejected from the material flow fully automatically via a pneumatically operated diverter.

Your advantages

Protection of machines, tools, products

Self-monitoring with diagnostic system

Fully automatic function

Universal application possibilities

Integrated electronics

Proven technology

Simple assembly

Simplest operation

Almost maintenance free

Catalogs

All-Metal Separators

16 Pages

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.