- Production Machines

- Cutting Machine

- Laser cutting machine

- Han's Laser Technology Co., Ltd

- Products

- Catalogs

- News & Trends

- Exhibitions

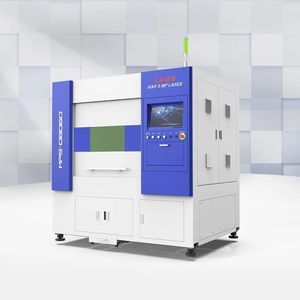

Laser cutting machine G3015-Jfor aluminumfor stainless steelfor brass

Add to favorites

Compare this product

Characteristics

- Technology

- laser

- Material

- for aluminum, for stainless steel, for carbon steel, for brass

- Product handled

- sheet metal

- Associated function

- forming

- Configuration

- compact, gantry type

- Other characteristics

- automatic, high-precision

- Cutting speed

120 m/min

- Laser power

Max.: 20,000 W

Min.: 6,000 W

- Repeatability

0.03 mm

(0.0012 in)- Overall length

8,000 mm

(315 in)- Overall width

2,800 mm

(110 in)- Height

2,000 mm

(79 in)- Load capacity

1,400 kg

(3,086 lb)

Description

Han's Laser's new G3015-J laser cutting machine is a high-tech product mainly used for cutting and forming carbon steel, stainless steel and aluminum alloy sheets, as well as other materials such as brass.

Rigid and Strong Structure: The machine bed and beam are made of high-strength carbon steel, which has undergone annealing and subsequent vibration aging. This design ensures the elimination of internal stress and provides exceptional stability. The hollow structure of the bed helps eliminate heat conduction during cutting, thus ensuring long-lasting stability and high precision in work.

Space Saving: The integrated design of the cabinet with the machine not only saves space, but also improves placement flexibility. Its compact format makes installation and maintenance easier. In addition, this design has allowed for optimized operating costs, as packaging and transportation are efficiently performed using only a standard 40-foot (40GP) container.

Intelligent Zoned Ventilation: The machine is equipped with a "zoning" ventilation system that features dual- and quad-row dust removal areas independently. This system uses high-sealing dampers that intelligently adjust based on the cutting job, automatically opening and closing for efficient dust removal and optimal ventilation.

Automatic oil pumping: The G3015-J's double-table structure has achieved automation of oil pumping thanks to a new electronic control device. This advancement eliminates the need for manual lubrication, improving production efficiency and ensuring operational reliability.

Other Han's Laser Technology Co., Ltd products

Sheet metal cutting

Related Searches

- Cutting system

- Metal cutting system

- CNC cutting system

- Laser cutting system

- Cutting machine for industrial applications

- Automatic cutting system

- Knife cutting system

- High-precision cutting system

- Sheet metal cutting system

- High-speed cutting system

- Fiber laser cutting system

- Tube cut-off machine

- Precision cutting system

- Fabric cutting system

- Aluminum cutting system

- SS cutting machine

- Sheet cutting system

- Metal fabrication cutting system

- Cutting machine for the automotive industry

- CE cutting system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.