- Robotics - Automation - Industrial IT

- Automation

- Production automation system

- Han's Laser Technology Co., Ltd

- Products

- Catalogs

- News & Trends

- Exhibitions

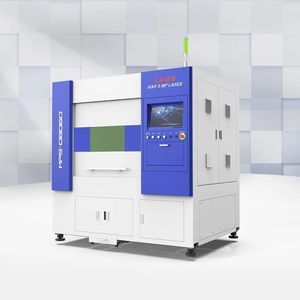

Production automation system tower

Add to favorites

Compare this product

Characteristics

- Options

- for production, tower

Description

Introducing Han's Laser Automation: Automatic Production Line , an innovative solution designed to revolutionize your laser machine operations. As a distributor of sheet metal forming machinery, we offer you a seamless integration of technology and efficiency with our advanced automation system.

Unattended Production: Experience the future of laser processing with fully automated production, reducing the need for manual intervention.

Reduce labor costs: Optimize your operations and reduce labor costs with our automated laser production line.

FMS Intelligent Scheduling System: Enjoy smart and efficient scheduling, optimizing your workflow for maximum productivity.

Deep Integration Self-Diagnostics: Benefit from an advanced integrated self-diagnostic system.

Technical advantages

- Storage tower (raw material storage): Automatic access to plates, compact structure, space saving and orderly management of material information.

- Automatic loading robot: Unique suction cup with independent vacuum. Oriented towards safety, zone control, flexibility to handle plates of different sizes.

- Automatic unloading robot: Comb-type fork structure, safe and reliable.

- Electric Double Layer Interchangeable Carts: Upper and lower layer interchangeable structure. Floor space saving. Continuous double station production without interruption.

Performance parameters

- Maximum sheet size: 8000*2500

- Number of layers: 10/12/15 floors (optional according to the height of the workshop)

- Maximum load per shelf: 3t. PLC+FMS+CNC (loading and unloading control system+intelligent programming system+cutting machine control module)

Other Han's Laser Technology Co., Ltd products

Sheet metal cutting

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.