- Power Transmission - Mechanical components

- Actuator and Positioning System

- Food feeder

- Hangzhou color powder coating equipment ltd

- Products

- Catalogs

- News & Trends

- Exhibitions

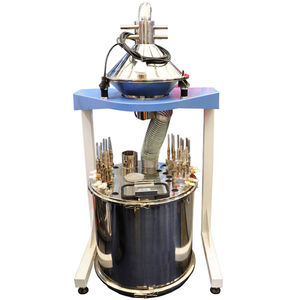

Food feeder colo-6000

Add to favorites

Compare this product

Characteristics

- Product applications

- food

Description

Powder center for fast color

changes and improvement

of productivity

TECHNICAL PARAMETERS

1. Pwer supply voltage: 1P 220VAC (110V)

2. Power: 500W

3. Air pressure: 0.6-0.8MP

4 Can be equipped with up to 16 powder pump

• Powder barrel lid design saves powder

• Original packaging for direct supply powder

• Nested structure design, cleans thoroughly

• High quality fluidization is achieved through

vibration from our newly designed fludized plate

and powder

• Powder-bit auto-detection alarm

• Increase the supply of new powder automatically

• Automatic matching of old and new powders

together.

ADVANCE FEATURES

The powder feed central system provides fast

color change. The automatic spray gun, various

powder hoses, and injectors will stay clean automatically

during color change. A filter system

maintains a comfortable indoor environment

by transferring dusts during cleaning. The unit

is fully programable.

The powder position sensor will detect the

position of the powder. A lack of powder will

signal a warning which will fluidized the

powder barrel: 100 liter capacity. The cover

extends the capacity and will prevent the

powder from wafting.

Shake table: If you do not use the fluidized

powder box, the powder can also be placed directly

in the original packing carton shock stage.

From there the powder can be pumped directly

from the carton supply to the powder gun. It

does not require cleaning when changing the

powder coating box.

The automatic sifter contains a screen which

removes impurities contained in the recovered

powder.

Control System: Touch screen operator panel

and keyboard input Increase the supply of new

powder automatically.

VIDEO

Other Hangzhou color powder coating equipment ltd products

Automatic reciprocator & Automatic powder application system

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.