- Production Machines

- Cutting Machine

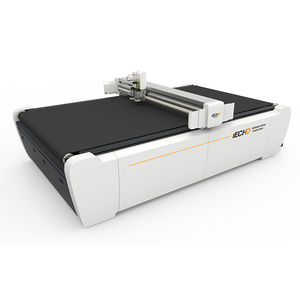

- Knife cutting machine

- Hangzhou IECHO Science & Technology Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Multi-ply cutting system GLSCknifefor polyesterfor fabrics

Add to favorites

Compare this product

Characteristics

- Technology

- knife

- Material

- for polyester, for fabrics

- Product handled

- bar, sheet

- Control type

- with digital assistance, manually-controlled, servo-driven, with programming software

- Associated function

- marking, multi-function, stacking, drilling, hole punch

- Applications

- for the automotive industry, for processing industry

- Workpiece loading

- automated loading/unloading

- Phase

- three-phase, single-phase

- Configuration

- large-format

- Other characteristics

- automatic, high-precision, high-productivity, high-efficiency, CE, ISO, for mass production, multi-ply

- Maximum cutting height

90 mm

(3.5 in)- Cutting speed

500 mm/s

- Overall length

5,172 mm

(204 in)- Overall width

3,207 mm

(126 in)- Height

2,600 mm

(102 in)- Weight

3 t

(3.31 us ton)

Description

New vacuum chamber design

Advantages of digital cutting

Automatic film mulching device

Knife sharpen compensation

GLS Automatic Multi-Ply Cutting System provides the best solutions for mass production in Textile,Furniture,Car interior, Luggage, Outdoor industries, etc. Equipped with IECHO high speed Electronic Oscillating Tool (EOT), GLS can cut soft materials with high speed,high precision and high intelligence. IECHO CUTSERVER Cloud Control Center has powerful data conversion module, which ensures GLS work with the mainstream CAD software in the market.

The fuselage frame is made of high-quality carbon structural steel, which is formed at one time by a large five-axis gantry milling machine to ensure the accuracy of the equipment.

Maximum rotating speed can reach 6000rpm. Through the optimization of dynamic balance, the noise during equipment operation is reduced, the cutting accuracy is guaranteed, and the service life of the machine head is increased. The high frequency vibration blade is made of special processing material to be more solid, and it is not easy to deform during the cutting process.

VIDEO

Catalogs

Other Hangzhou IECHO Science & Technology Company products

Digital Cutting Systems

Related Searches

- Cutting system

- Metal cutting system

- Cutting machine for industrial applications

- Automatic cutting system

- Knife cutting system

- High-precision cutting system

- Sheet metal cutting system

- High-speed cutting system

- Plastic cutting system

- Precision cutting system

- Fabric cutting system

- Aluminum cutting system

- Sheet cutting system

- Cutting machine for the automotive industry

- CE cutting system

- High-performance cutting system

- High-efficiency cutting system

- Three-phase cutting system

- Compact cutting system

- Engraving cutting system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.