- Machine-tools

- Finishing Machine

- Internal thread grinding machine

- Hanjiang Machine Tool Co., Ltd

- Products

- Catalogs

- News & Trends

- Exhibitions

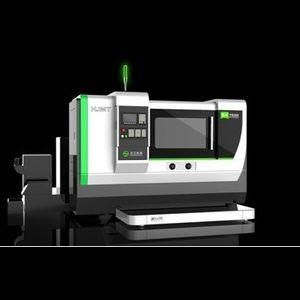

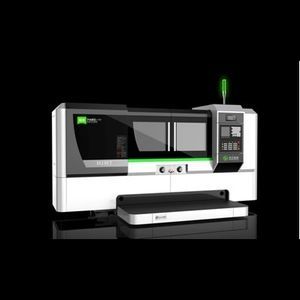

Internal thread grinding machine SK7612ball screwCNC

Add to favorites

Compare this product

Characteristics

- Type

- internal thread

- Applications

- ball screw

- Control type

- CNC

- Spindle speed

Min.: 0 rpm

(0 rad.min-1)Max.: 85 rpm

(534 rad.min-1)

Description

The machine is mainly used to grind thread nuts with gothic grooves, suitable for automobile steering worms and ball screws in batch production。

【NC system configuration】

1、SIEMENS 828D, controlling 4 NC axes

2、Axis X: Cross feed of wheelhead full close-looped

Axis Z: Longitudinal table traverse

Axis C: Rotation of work spindle

Axis A: swiveling of helix angle

【Working accuracy】

Thread accuracy obtainable

Limit lead error 0.005mm

Accumulative error at a length of50mm 0.009mm

【Technical characteristics】

1、Wheel dressing is made by a formed diamond roller to achieve rapid and precise wheel dressing

2、Adopting a newly-developed workhead structure doubles work spindle speed, thus increasing greatly machine productivity

3、Special-built soft program makes the machine have automatic grinding cycle, wheel dressing and self-compensation for wheel dressing amount

4、Wheel spindle employs a high speed E-spindle

5、Users can use one-way or two-way auto-grinding cycle function

6、Online device for pre-cut thread alignment can be an optional configuration to users

7、Efficient centrifugal oil mist exhauster is available

Other Hanjiang Machine Tool Co., Ltd products

PRODUCTS SHOW

Related Searches

- Grinding machine

- CNC grinding machine

- Precision grinding machine

- Workpiece grinding machine

- Cylindrical grinding machine

- 3-axis grinding machine

- High-speed grinding machine

- Hydraulic grinding machine

- Hydrostatic grinding machine

- Direct-drive grinding machine

- 5-axis grinding machine

- 6-axis grinding machine

- Ball screw grinding machine

- 4-axis grinding machine

- Internal thread grinding machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.