- Machine-tools

- Finishing Machine

- Workpiece grinding machine

- Hanjiang Machine Tool Co., Ltd

- Products

- Catalogs

- News & Trends

- Exhibitions

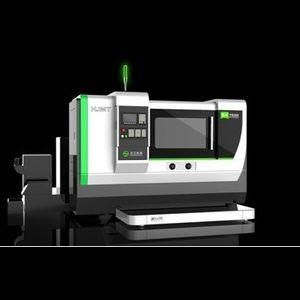

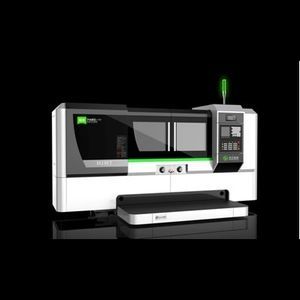

Workpiece grinding machine SK7432 seriesball screwCNC5-axis

Add to favorites

Compare this product

Characteristics

- Applications

- workpiece, ball screw

- Control type

- CNC

- Number of axes

- 5-axis

- Other characteristics

- hydrostatic

Description

The machine is mainly used for grinding of screws with Whitworth & Acme thread and ball-screws precisely

【NC system configuration】

1、Equipped with a SIEMENS 828D CNC system, the machine is controlled with five programmable axes including three synchronous ones。

2、No. of programmable axes

Axis Z: Table longitudinal traverse

(With grating scale) full close-looped

Axis X: Cross-feed of wheelhead

(With grating scale) full close-looped

Axis C: Rotation of work spindle

(With angular encoder) full close-looped

Axis V: Vertical feed of dresser slider

Axis W: Horizontal feed of dresser slider

Out of above NC axes, C-axis and Z-axis are linked to perform thread movement;Wheel dressing is conducted by a formed diamond roller;Two electric hand-wheels can control each NC axis by hand。

【Working accuracy】

1、ball-screws: P3 (GB/T17587.3-1998) (ISO3408-3:2006), measured under dynamic state

2、Acme screws: P6 (JB2886-1992)

【Technical characteristics】

1、Employing a rear-mounted wheel spindle supported by hydro-static bearings, workpiece surface improves greatly。

2、The optimized workhead structure makes work spindle speed double, thus improving machine efficiency greatly。

3、The optimized CNC wheel dresser can dress grinding wheel into various required profiles

4、Oil chiller, high-flow and powerful cooling system and double-filtering system together ensure the temperature influence in grinding process to the minimum。

5、With the intelligent grinding software in man-computer interactive conversation , wheel dressing and grinding can be operated with convenience and accuracy。

Other Hanjiang Machine Tool Co., Ltd products

PRODUCTS SHOW

Related Searches

- Grinding machine

- CNC grinding machine

- Precision grinding machine

- Workpiece grinding machine

- Cylindrical grinding machine

- 3-axis grinding machine

- High-speed grinding machine

- Hydraulic grinding machine

- Hydrostatic grinding machine

- Direct-drive grinding machine

- 5-axis grinding machine

- 6-axis grinding machine

- Ball screw grinding machine

- 4-axis grinding machine

- Internal thread grinding machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.