- Products

- Hanjiang Machine Tool Co., Ltd

- Products

- Catalogs

- News & Trends

- Exhibitions

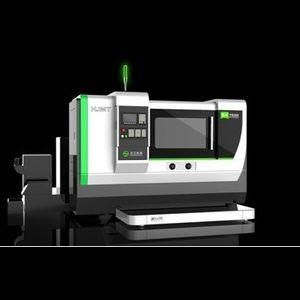

Ball screw whirling machine HJ092×80

Add to favorites

Compare this product

Characteristics

- Applications

- for ball screw

- Diameter

Max.: 230 mm

(9.06 in)Min.: 40 mm

(1.57 in)- Working length

Max.: 8,000 mm

(314.96 in)Min.: 2,000 mm

(78.74 in)

Description

The machine is made to hard-mill ball-screws and Acme screws, able to machine job diameter under100mmbut longer its specification by putting them through bore of the work spindle。

【NC system configuration】

【Working accuracy】

The accuracy of ball-screw machined is up to grade P5

The accuracy of Acme screw machined is up to grade 8

【Technical characteristics】

1、The bed is made of qualified cast-iron with high strength

2、The tool spindle is supported by rolling bearings, and its rotation is driven by an AC motor regulated with a frequency converter, so it runs at a constant peripheral speed

3、Work spindle is driven by an AC servo motor;able to auto-index. A precise angular encoder mounted at the end of the spindle, serving as a reference element of rotation & indexing。

4、The cutter carriage can travel crossly, and each movement is driven by AC servo motor, driving a precision ball-screw to achieve rapid advance and retreat, periodical feeding and auto-compensation for job pitch diameter。

5、Hardness of thread flanks can not be decreased because of hard-milling

6、The machining cost can be reduced by use of mountable & indexing CBN inserts

7、The machining zone is cooled with compression air, so the pollution caused by coolant can be eliminated。

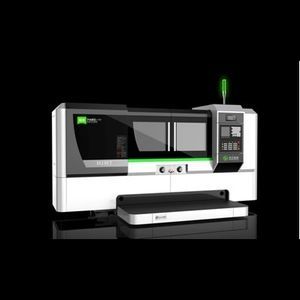

Other Hanjiang Machine Tool Co., Ltd products

PRODUCTS SHOW

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.