- Machine-tools

- Finishing Machine

- CNC grinding machine

- Hanjiang Machine Tool Co., Ltd

- Products

- Catalogs

- News & Trends

- Exhibitions

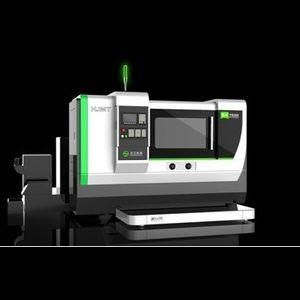

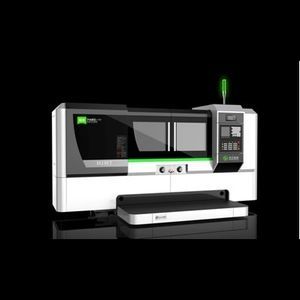

CNC grinding machine SK74053-axis

Add to favorites

Compare this product

Characteristics

- Control type

- CNC

- Number of axes

- 3-axis

- Spindle speed

Min.: 1 rpm

(6 rad.min-1)Max.: 80 rpm

(503 rad.min-1)- Distance between centers

150 mm

(6 in)

Description

This machine is mainly used to grind precisely thread grooves of small screw for batch manufacturing

【NC system configuration】

1、CNC system

SIEMENS 828D,controlling 3 NC axes

2、NC axis details

Axis Z: Longitudinal table traverse

(With grating scale) full close-looped

Axis X: Cross feed of wheelhead

(With grating scale) full close-looped

Axis C: Rotation of work spindle

(With circular grating scale) full close-looped

【Working accuracy】

Accuracy class obtainable (single-rib)

2π at a periodic pitch 0.004mm

Over the entire length of screw 0.006mm

Roughness Ra 0.32μm

【Technical characteristics】

1、Equipped with an automatic clamping mechanism to achieve fast clamping of workpiece

2、An auto-alignment device to match pre-cut thread groove is provided

3、Wheel dressing is conducted by a formed diamond roller to effectively achieve wheel dressing

4、Multi-rib grinding process can make a high production of screw grinding

5、Single-rib grinding process can realize a high precision of screw grinding

6、A full-closed housing and an efficient centrifugal oil mist exhauster are

Other Hanjiang Machine Tool Co., Ltd products

PRODUCTS SHOW

Related Searches

- Grinding machine

- CNC grinding machine

- Precision grinding machine

- Workpiece grinding machine

- Cylindrical grinding machine

- 3-axis grinding machine

- High-speed grinding machine

- Hydraulic grinding machine

- Hydrostatic grinding machine

- Direct-drive grinding machine

- 5-axis grinding machine

- 6-axis grinding machine

- Ball screw grinding machine

- 4-axis grinding machine

- Internal thread grinding machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.