- Machine-tools

- Finishing Machine

- Cylindrical grinding machine

- Hanjiang Machine Tool Co., Ltd

- Products

- Catalogs

- News & Trends

- Exhibitions

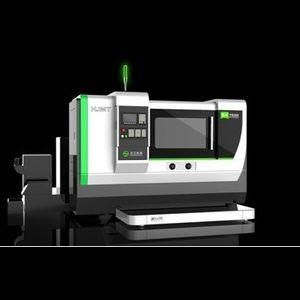

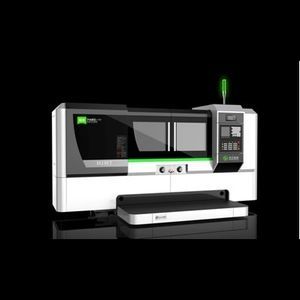

Cylindrical grinding machine SK7720BCNC6-axisdirect-drive

Add to favorites

Compare this product

Characteristics

- Type

- cylindrical

- Control type

- CNC

- Number of axes

- 6-axis

- Features

- direct-drive

- Spindle speed

Max.: 45 rpm

(283 rad.min-1)Min.: 1 rpm

(6 rad.min-1)- Distance between centers

750 mm

(30 in)

Description

This machine is used to grind various cylindrical worms (ZA, ZN, ZI, ZK, ZC1), and also can be used to grind trapezoidal screws。

【NC system configuration】

No. of programmable axes: six

Axis Z: table longitudinal traverse

(With grating scale) full close-looped

Axis X: wheelhead cross feed

(With grating scale) full close-looped

Axis C: Rotation of work spindle

(With angular encoder) full close-looped

Axis A: Helix angle swivel

(With angular encoder) full close-looped

Axis V: Vertical feed of dresser slider

Axis W: Horizontal feed of dresser slider

【Working accuracy】

Cylindrical worms:

when thread start=1-2, the accuracy is up to grade 4;when thread start≥3,the accuracy is up to grade 5( by GB standard)。

Trapezoidal screws: the accuracy is up to grade 6 (by GB standard)。

【Technical characteristics】

1、With double diamond discs, grinding wheel is dressed into required thread profiles。

2、Wheel spindle is driven directly by a high-powered built-in permanent magnet synchronous motor (PMSM) to get a high power and low vibration。

3、The adjustment of helix angle is done and locked automatically, precise and fast。

4、The two diamond discs is driven by AC servo motor, ensuring a constant speed and low vibration。

5、With a manual alignment device provided for pre-cut thread match, it is suitable for batch manufacturing。

6、A dynamic balancing system and an on-line automatic aligning device can by provided if optioned by the user。

7、A full-closed cover and an oil-mist extractor are provided with the machine to improve working environment。

Other Hanjiang Machine Tool Co., Ltd products

PRODUCTS SHOW

Related Searches

- Grinding machine

- CNC grinding machine

- Precision grinding machine

- Workpiece grinding machine

- Cylindrical grinding machine

- 3-axis grinding machine

- High-speed grinding machine

- Hydraulic grinding machine

- Hydrostatic grinding machine

- Direct-drive grinding machine

- 5-axis grinding machine

- 6-axis grinding machine

- Ball screw grinding machine

- 4-axis grinding machine

- Internal thread grinding machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.