- Power Transmission - Mechanical components

- Mechanical Transmission

- Planetary gear reducer

- Hansen Industrial Transmissions

- Products

- Catalogs

- News & Trends

- Exhibitions

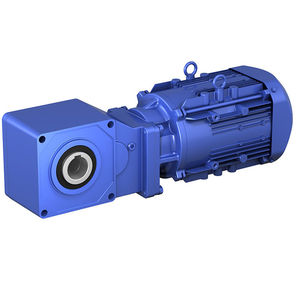

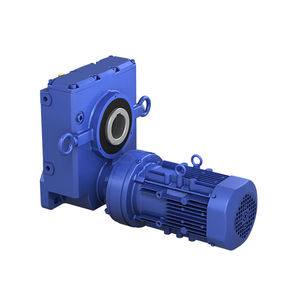

Planetary gear reducer Cyclo®coaxialsolid-shaft100 - 200 Nm

Add to favorites

Compare this product

Characteristics

- Type

- planetary

- Shaft orientation

- coaxial

- Shaft configuration

- solid-shaft

- Torque

- 100 - 200 Nm, 50 - 100 Nm, > 10 kNm, 500 - 1000 Nm, 1 - 2 kNm, 2 - 5 kNm, 5 - 10 kNm

- Configuration

- flange

- Applications

- shaft

- Other characteristics

- vertical

- Gear ratio

Max.: 658,503 unit

Min.: 6 unit

Description

Detect overloads instantaneously with installed torque limiter

Cyclo® reducer with installed torque limiter to detect overloads

Protects your valuable machines from catastrophic failure.

The torque limiting is applied at the drive part, allowing you a more accurate examination of your device safety factor, which makes optimal equipment design possible.

Product Features

Compact

Compact Cyclo® reducer boasts a high reduction ratio, high efficiency, and a small number of parts, including a superior built-in torque sensor (spring / limit switch type, load cell type).

High Accuracy and Reliability

The sensor base consists of coiled springs or load cells, and features high accuracy and reliability. (Accuracy of configured torque ±5 - ±10%)

Allows for Economical Equipment Design

The torque limiting is applied at the drive part, allowing you a more accurate examination of your device safety factor, which makes optimal equipment design possible.

Operates During Momentary Overload

The mechanical torque detection mechanism allows for a shorter detection time compared to thermal relays, detecting overloads instantaneously.

Wide Range of Torque Adjustment

The adjustment range for configuring the torque is a wide ±25%, which means adjustments can easily be made on-site to match the actual torque of the equipment. (However, it must be within the maximum and the minimum configured torque).

Safe Unattended Operation

Built-in buzzer and indicator light in the motor operation circuit ensures a safe unattended operation. By using either the double or triple safety models, it is also possible to drive the auxiliary motor for a thickener shaft.

Combine with Other Protection Equipment

Catalogs

Other Hansen Industrial Transmissions products

Gears & Gearmotors

Related Searches

- Planetary gearbox

- Coaxial gearbox

- Right angle gearbox

- Precision gearbox

- Compact gearbox

- Gear train gearbox

- Solid-shaft gearbox

- Hollow-shaft gearbox

- Industrial gear reducer

- Transmission gearbox

- Shaft gearbox

- Helical gear gearbox

- Multi-stage gearbox

- Single-stage gearbox

- Two-stage gearbox

- Machine gearbox

- Bevel gearbox

- High-performance gearbox

- Electric motor gearbox

- Modular gearbox

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.