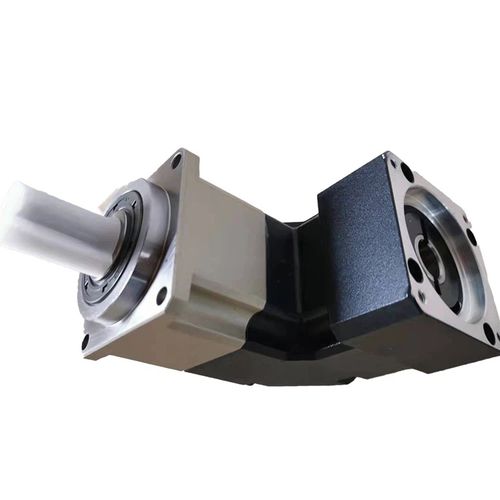

PGHR060 Planetary speed reducer is compact components designed to optimize torque transmission in various applications. These mechanisms enable the delivery of high torque levels while reducing the motor's required revolutions for a given power output.

What is a planetary speed reducer?

Compact devices meant to maximize torque transmission in different uses are planetary gear reducers. The systems guarantee the high torque levels' transfer and simultaneously lower the necessary motor rotations for a given power level.

PGHR060 Compact parts meant to maximize torque transmission in different uses are planetary gear reducers. These systems lower the motor's necessary revolutions for a given power output while also allowing the delivery of high torque levels.

One gearbox with aligned input and output shafts makes up the reducers. Planetary speed reducer is absolutely essential in industrial automation systems like DC transmission, servo, and stepping systems in effectively managing jobs requiring high torque.

Which is Featrue of a planetary gear reducer?

Excellent translocation of accuracy

Excellent transmission precision is well-known of PGHR060 planetary speed reducer. Using high-precision gear assembly, several planetary gears' meshing distributes the load, thus improving uniform transmission and so lowering gear mesh clearance. Usually 3-5 arc minutes, its low return clearance may satisfy the high criteria of precision equipment for position control, particularly fit for high-precision servo drive and stepper motor systems.