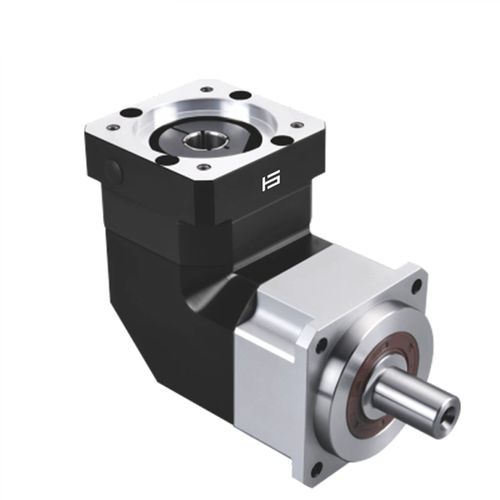

The PGHR090 gear reducers feature a robust, industrial-grade design and plug-and-play compatibility with leading brands, making it versatile enough to suit nearly any application.

In mechanical transmission systems, gear reducers are mechanical devices mostly used to lower the speed and raise the torque. Usually, it comprises of a set of gears that mesh to translate the high speed produced by the motor or engine into a lower speed output and thereby raise the output torque.

The PGHR090 gear reducer feature a robust, industrial-grade design and plug-and-play compatibility with leading brands, making it versatile enough to suit nearly any application.

What is Structure of gear reducer

Input Shaft

the shaft powered from the source-that of a motor, for example.

A gear train is a mechanism of interlocking gears in charge of changing torque and speed.

Output Shaft

Deliver the connected machinery with the adjusted speed and torque from output shaft.

Real Estate

A structure with structural integrity and protection of internal components.

Key to the reducer's operation is the gear ratio, which is found within the gear train inside it. The gear ratio is the output gear's teeth count relative to the input gear. A 10:1 gear ratio, for instance, greatly increases torque by implying the input shaft rotates 10 times for each single rotation of the output shaft.

How are Gear Reducers use for?

Gear reducers are fundamental in many different fields since they enhance speed and torque to meet specific application requirements. Their ability to modify motor performance makes them absolutely indispensable in many mechanical and industrial operations.