what are the Advantages?

High speed ratio

Without the need for extremely complex mechanisms, a high-speed reduction ratio device of (1/30) to (1/320) can be achieved in one stage of deceleration.

Small back gap

The HD harmonic reducer has a very small backlash value, which is different from the meshing method of general gears and is an essential feature for precision control of control mechanisms.

high-precision

The number of teeth meshing simultaneously is high, and the two symmetrical positions at 180 ° also mesh simultaneously, which affects the gear pitch error and cumulative pitch error of the rotation accuracy. Due to averaging, it can achieve extremely high requirements for position accuracy and rotation accuracy.

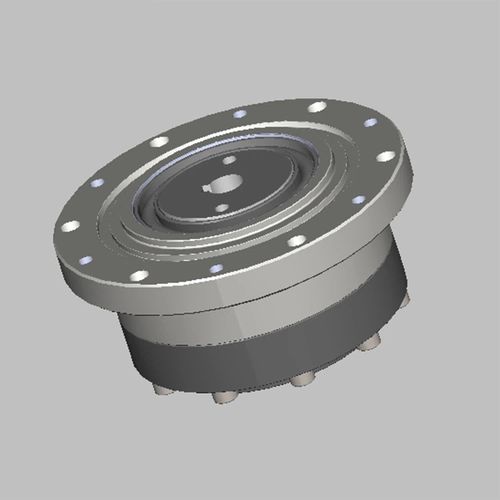

Few basic components, simple combination

Even at high reduction ratios, it is still composed of three basic components, and because they are on the same axis, the assembly of component-based products is simple, and the structural design can be simplified.

Small and lightweight

Under the same torque and speed ratio conditions, compared to traditional gear reducers, it only requires (1/3) of the volume and (1/2) or less of the weight. The device can be small and lightweight.

High torque

The Flex Spline is made of special steel with extremely high fatigue strength. Its transmission method is different from the general power transmission method, and the number of meshing teeth at the same time is about 30% of the total number of teeth. However, due to the full contact of the teeth, the force on each tooth is extremely small, resulting in a large output torque.