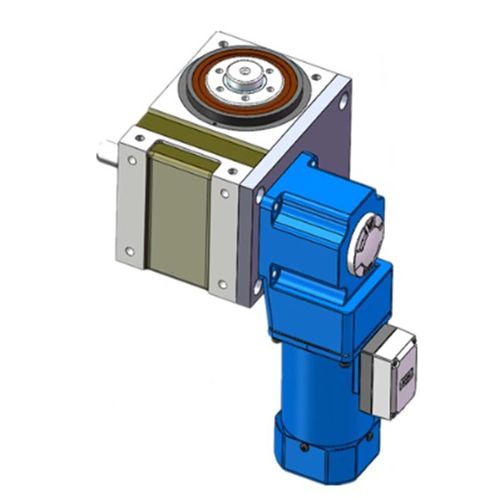

Hansheng's cam index drives with Motors are available in various motor connection options, including horizontal direct connection, vertical connection, vertical synchronous connection, and horizontal synchronous connection.

In production systems and automation, cam index drives with motors are precision mechanical devices used for intermittent motion. They translate motor continuous rotational action into a precise, indexed stop-and-go motion. Applications ranging from assembly machines to conveyors to packaging systems make frequent use of these drives.

Usually using a globoidal cam mechanism and a fixed turret or output shaft, a cam index drive has a torque capacity of 500 Nm, for example, may support high load demanding indexing systems. Usually a servo or stepper motor, the motor offers a constant rotational input; the cam guarantees a flawless and exact output movement. Usually depending on the model and motor combination, speeds range from 20 to 200 RPM. As high as ±0.02°, the indexing accuracy guarantees that the system can manage precision chores including component feeding or pick-and-place.

These drives are also flexible for a range of automation systems since they allow one to customize their number of stops-e.g., 6, 8, or 12 stations-and dwell time.

High precision, dependability, and longevity in automation systems define cam index drives with motors.