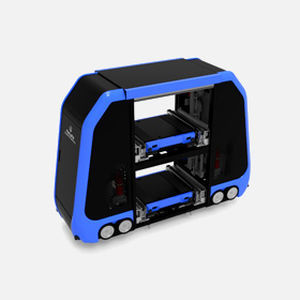

Automatic materials handling system for batteryindustrialstorage

Add to favorites

Compare this product

Characteristics

- Operating mode

- automatic

- Product applications

- for battery

- Applications

- industrial, storage

Description

The precise measurement and mixing of the materials are performed to ensure reactivity and uniformity in the kiln and satisfy the raw materials' physical and chemical characteristics of the rechargeable battery electrode (positive and negative). Additional processes, such as controlling the particle size of the final products, and removing the residual lithium and foreign metal particles, are performed on the final product to prevent fire hazards and satisfy the charge and discharge performances. The EPC Turn-Key Project can be performed with nine processes: raw material storage, weighing, mixing, grinding, crushing, raw material transfer, water washing, dehydration, drying, cooling classification, de-ionization, and packaging.

Spec

CAPA. 1,500 ton/month production process

Hi Ni single crystal / polycrystal

NCA single crystal / polycrystal

Anode material (graphite, Si, special material) processing line

Process conditions: O2, N2, CO2 Free

Catalogs

No catalogs are available for this product.

See all of HANWHA MACHINERY‘s catalogsRelated Searches

- Forklift truck

- Pallet jack

- Lifting system

- Electric forklift truck

- Electric pallet jack

- Electric transfer car

- High-performance forklift truck

- Charging machine

- Autonomous mobile robot

- Goods lift

- Automated materials handling system

- Automated loading system

- Transfer car with platform

- AGV forklift truck

- Industrial materials handling system

- Warehouse autonomous mobile robot

- Transfer autonomous mobile robot

- AGV pallet truck

- Collaborative AGV

- Storage materials handling system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.