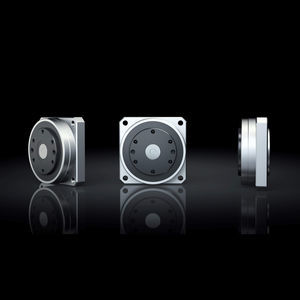

Strain wave gear reducer CPU-H coaxialhollow-shaft200 - 500 Nm

Add to favorites

Compare this product

Characteristics

- Type

- strain wave

- Shaft orientation

- coaxial

- Shaft configuration

- hollow-shaft

- Torque

- 200 - 500 Nm, 20 - 50 Nm, 100 - 200 Nm, 50 - 100 Nm, 500 - 1000 Nm, 1 - 2 kNm, 5 - 10 Nm, 10 - 20 Nm

- Performance

- high-precision

- Applications

- for servo motors, drive, for milling machines, for grinding machines

- Other characteristics

- stainless steel

- Rotational speed

Max.: 8,500 rpm

(53,407.08 rad.min-1)Min.: 3,000 rpm

(18,849.56 rad.min-1)- Gear ratio

Max.: 160 unit

Min.: 30 unit

Description

The CPU Gears with output bearing are available in nine sizes with gear ratios of 30, 50, 80, 100, 120 and 160:1 offering repeatable peak torques from 9 to 1840 Nm and zero backlash.

3 clever versions: for direct motor mounting, with hollow shaft or with stainless steel input shaft

The gear's high precision output bearing with high tilting capacity allows direct attachment of heavy payloads without the need for further support, thereby providing simple and space saving design installations. The CPU Series is available in three versions: the CPU-M Gears with output bearing for direct mounting of any servo motor, the CPU-H Gears with output bearing with hollow shaft to feed through supply lines for further drive systems and the CPU-S Gears with output bearing with stainless steel input shaft enabling flexible integration into your design. If required, the gears with output bearing are available as specific configurations tailored to your application, or with particularly high corrosion protection. The high capacity output bearing with maximum tilting rigidity and precision allows that the gears can quickly and easily absorb high payloads and feature long service life. The gears with output bearing are fully sealed and ran thus ideally suited for use in harsh ambient conditions. The gears with output bearing accurate positioning guarantees stable machine characteristics with short cycle times guaranteed.

Markets

Machine tools

Printing machines

Medical technology

Applications

Machining center

Dental milling machines

Grinding machines

Digital printing machines

Diagnostic imaging

Catalogs

Related Searches

- Planetary gearbox

- Coaxial gearbox

- Precision gearbox

- Gear train gearbox

- Compact gearbox

- Solid-shaft gearbox

- Hollow-shaft gearbox

- Industrial gear reducer

- Transmission gearbox

- Shaft gearbox

- Helical gear gearbox

- Flange gearbox

- High-precision gearbox

- Robot gearbox

- High load capacity gearbox

- Drive gearbox

- Servo motor gearbox

- Machine tool gearbox

- Machine gear reducer

- Large gearbox

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.