Stainless steel housing flangerectangularfor vehicles

Add to favorites

Compare this product

Characteristics

- Construction

- flange

- Configuration

- rectangular

- Material

- stainless steel

- Application

- for vehicles, electronic equipment

- Other characteristics

- manufacturing

Description

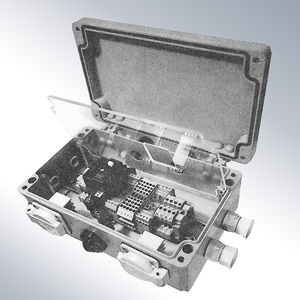

Konecranes is a world leader in the lifting business sector, providing innovative lifting solutions to companies in the manufacturing and process industries, shipyards and ports. With around 400 employees, Konecranes Noell GmbH in Würzburg develops and produces the so-called straddle carriers (German: Portalstapler or Portalhubwagen). They are mainly used in container ports where they are deployed to transport and stack containers incoming and outgoing by ship, rail and lorry. The straddle carriers consist of a frame and a lifting device (spreader), which can be moved vertically by means of hoisting winches, suspended between the frames. The frame is equipped with a chassis with wheels. The operator's cabin is flange-mounted to the top of one end face of the frame. The straddle carrier moves over a container and then the spreader is locked with the four corner fittings of the container so that it can be lifted. Konecranes has now been building these vehicles for more than 50 years and can look back on a total number of more than 3,600 straddle carriers delivered worldwide.

Over the years, the straddle carriers have undergone continuous further development, particularly in the field of electronics. As the enclosures are mounted on a vehicle they are subject to considerable loads which had to be taken into account in the design. The company was therefore looking for a manufacturer with the technical know-how that could offer a reliable solution so that the end product could be used reliably and long-lastingly, even under the toughest conditions. It was, and is, important to Konecranes to find a manufacturer that produces high-quality control cabinets.

Catalogs

No catalogs are available for this product.

See all of häwa GmbH‘s catalogsExhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- Häwa rectangular enclosure

- Plastic box

- Wall-mounted enclosure

- Terminal box

- Metal box

- Compact box

- Aluminium enclosure

- Custom box

- Electronic equipment housing

- Watertight enclosure

- Power distribution casing

- Modular box

- Network cabinet

- Enclosure with door

- IP66 housing

- Stainless steel housing

- Wire junction box

- Control housing

- Floor-mounted network cabinet

- Waterproof electric cabinet

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.