Asynchronous motor 10000 Vsubmersible

Add to favorites

Compare this product

Characteristics

- Type

- asynchronous

- Voltage

- 10000 V

- Other characteristics

- submersible

- Power

Min.: 0 W

(0 hp)Max.: 2,500,000 W

(3,399.053 hp)

Description

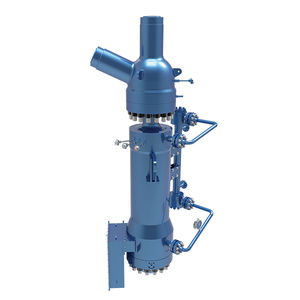

Submersible Motors

High reliability, fluid-filled, electro-submersible motors designed to save topside space while providing over 8 years between maintenance cycles.

Design Features of Hayward Tyler Submersible Motors

Our electro-submersible motors can be arranged in standard or inverted configurations to suit the most demanding applications. We use a wet-wound, water/glycol filled motor that is environmentally friendly and has “run with leak” capability.

• Wet-wound, water/glycol filled motor.

• Injection molded cable joints

• Enclosed to IP68

• Variety of materials available, up to Super Duplex

• 8+ year service intervals

• Product lubricated bearings (radial and thrust)

• Integral thrust bearing/aux. impeller for improved cooling

• Run with leak capability

• Header tank available for visual condition check

• Condition monitoring using Motor Current Signature Analysis available as an option

Applications

Hayward Tyler Submersible Motors are ideal for applications such as:

Seawater Lift

Firewater Lift

Caisson Drain Pump

Hull Ballast and De-Ballast Pumps

Water Injection

Cooling Water Pumps

Booster Pumps

Jockey Pumps

Process Pumps

Marine Thrusters

Marine Secondary Propulsion

Mud Rise Pumps

Petrochemical Fluids

Cavern Pumps

Typically Used On:

FPSO

FLNG

Offshore Windfarms

Fixed Platforms

Tension Leg Platforms

Catalogs

No catalogs are available for this product.

See all of Hayward Tyler®‘s catalogsRelated Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.