- Industrial machines and equipment

- Heat Exchanger and Refrigeration

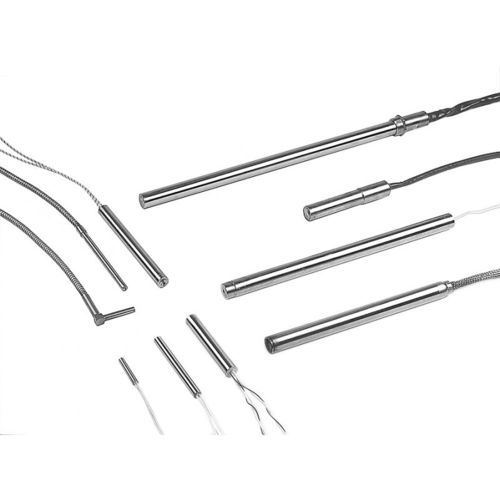

- Stainless steel cartridge heater

- heatsystems GmbH & Co. KG

Stainless steel cartridge heater

Add to favorites

Compare this product

Characteristics

- Material

- stainless steel

Description

Heating cartridges are mainly used for efficiently heating tools and workpieces. To this effect, the heating cartridges are pushed into a hole in the tool and fixed there. Different diameters and designs make sure that the temperature distribution matches the specifications as well as possible.

Electrical heating cartridges can be produced for a variety of diameters. The following list shows the most frequent diameters; in addition, many intermediate dimensions are available.

I. Metric dimensions

4 mm

6,5 mm

8 mm

10 mm

12,5 mm

16 mm

20 mm

25 mm

32 mm

II. Imperial dimensions

1/4" (6,35 mm)

3/8" (9,53 mm)

1/2" (12,7 mm)

3/4" (19,05 mm)

1" (25,4 mm)

Today, electrical heating cartridges are mainly made of corrosion-resistant stainless steel. Due to the past, heating cartridges with a brass sheath can still be found. The disadvantage of brass is a worse resistance against chlorine (e.g. for the processing of PVC); the lower prospensity to corrosion is an advantage over stainless steel.

Materials for the heating cartridge sheath:

Corrosion-resistant stainless steel

Brass

Heat-resistant stainless steel

If the heating cartridge is not used for heating a workpiece but for liquids, this can be taken into account during the selection of materials in many cases.

Available materials of the heating surface:

Carbon steel

Corrosion-resistant stainless steel

Heat-resistant stainless steel

Titanium, Hastelloy, special materials

Copper-nickel

Catalogs

No catalogs are available for this product.

See all of heatsystems GmbH & Co. KG‘s catalogsRelated Searches

- Vessel

- Heat exchanger unit

- Liquid/liquid heat exchanger

- Resistance heater

- Water vessel

- Heater

- Tubular heat exchanger

- Stainless steel heat exchanger

- Gas heater

- Water tank

- Air heater

- Electric heater

- Liquid heater

- Immersion heater

- Tubular resistance heater

- Cartridge heater

- Circulation heater

- Convection heater

- Flat resistance heater

- Ceramic resistance heater

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.