- Environment - Health - Safety

- Waste Treatment

- Incinerator

- heatsystems GmbH & Co. KG

Incinerator

Add to favorites

Compare this product

Description

The safe inactivation of contaminated exhaust-air from fermenters and autoclaves is unambiguously required by the German genetic technology safety regulations (GenTSV). In case of a biological contaminations the thermal treatment for inactivation is an accepted process.

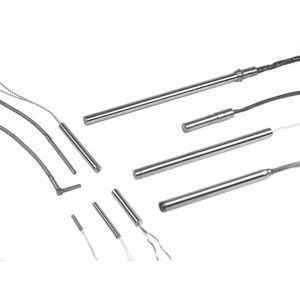

This incinerator causes the contaminated exhaust-air to flow through a bulk of stainless steel balls which are heated to process temperature. The chamber size of the incinerator and the required contact time are selected on the basis of customer requirements such that a safe thermal inactivation is ensured.

The incinerator is designed for heating the following fluids:

I. Exhaust-air from

Fermenters

Autoclaves

Waste water ducts (for ventilation)

optionally usable for

Catalytic cleaning of air (zero air)

Flue-gas cleaning

The fluid to be heated and the application temperature mainly define the materials which can be used for the unheated and/or heated surfaces.

Materials of the bulk:

Corrosion-resistant stainless steel

Aluminium oxide

Materials of the wetted components:

Corrosion-resistant stainless steel

Heat-resistant stainless steel

Catalogs

No catalogs are available for this product.

See all of heatsystems GmbH & Co. KG‘s catalogsRelated Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.