- Industrial machines and equipment

- Surface Treatment Equipment

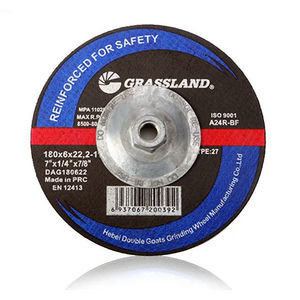

- Surfacing wheel

- Hebei Double Goats Grinding Wheel Manufacturing Co., Ltd

- Products

- Catalogs

- News & Trends

- Exhibitions

Surfacing wheel DAG1250622for polishingcuttingcylindrical

Add to favorites

Compare this product

Characteristics

- Function

- grinding, for polishing, cutting

- Type

- cylindrical

- Abrasive

- resin-bonded diamond

- Diameter

125 mm

(4.92 in)

Description

1.Will inferior abrasive discs cause safety accidents?

If the grinding wheel breaks, the resulting debris is likely to eject at high speed, and may cause serious injury or even death, usually hitting the face and head of the operator. The power of speed is indeed surprising, up to 80 to 100 miles per hour.

Grassland abrasives discs manufactured to assure operator safety and optimum performance with stable quality, guaranteed to comply with European safety standard EN 12413.

2.Why is it necessary to be equipped with appropriate safety clothing and protection during cutting or grinding fabrication?

During work and grinding, abrasive particles fall off due to friction. These are usually regarded as sparks, which can cause burns to bare skin and are especially damaging if they come into contact with the eyes. If you don’t wear earmuffs for a long time, your hearing will be affected.

3.How do you implement quality control for abrasive products?

We treat quality as our lifeblood, and have established a quality information traceability system for the whole manufacturing process, from the inspection of raw materials to the delivery of finished products.

A.well-equipped raw material laboratory to test all incoming raw materials as the first step of our quality control process.

B.Each production machine is attended by a professional to test the semi-finished products.

C.After the products are hardened, physical and performance tests are carried out on samples at a certain ratio. For all orders, samples are retained and test records are filed, allowing each batch of contracts to be made retrievable.

Other Hebei Double Goats Grinding Wheel Manufacturing Co., Ltd products

METAL GRINDING WHEEL

Related Searches

- Sanding disc

- Surface treatment wheel

- Cylindrical grinding wheel

- Metal sanding disc

- Surfacing wheel

- Grinding sanding disc

- Flap disc

- Diamond grinding wheel

- Aluminum sanding disc

- Flat grinding wheel

- Aluminum oxide sanding disc

- Cut-off wheel

- Finishing flap disc

- Polishing wheel

- Angle grinder grinding wheel

- Resin abrasive disc

- Aluminum oxide grinding wheel

- Deburring grinding wheel

- Dressing wheel

- Silicon carbide grinding wheel

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.