- Industrial machines and equipment

- Surface Treatment Equipment

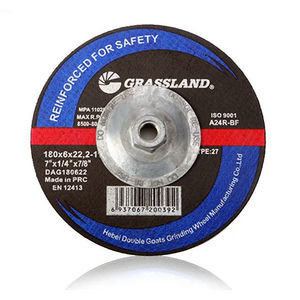

- Surfacing wheel

- Hebei Double Goats Grinding Wheel Manufacturing Co., Ltd

- Products

- Catalogs

- News & Trends

- Exhibitions

Surfacing wheel DSC2303223cut-offcylindricalresin-bonded diamond

Add to favorites

Compare this product

Characteristics

- Function

- grinding, cut-off

- Type

- cylindrical

- Abrasive

- resin-bonded diamond

- Diameter

230 mm

(9.06 in)

Description

1.What is the better Storage method of grinding wheel?

Store wheels on a suitable position in a dry condition, Never store wheels near excessive heat or cold, in contact with water, oil or moisture.

3.Why is it necessary to be equipped with appropriate safety clothing and protection during cutting or grinding fabrication?

During work and grinding, abrasive particles fall off due to friction. These are usually regarded as sparks, which can cause burns to bare skin and are especially damaging if they come into contact with the eyes. If you don’t wear earmuffs for a long time, your hearing will be affected.

5.Does Abrasive Wheel Have an Expiration Date?

Resin-bonded abrasive wheels should be used within three years from the date of manufacture. This assumes you’ve stored the wheels according to the manufacturer’s recommendations. While it may be possible to use resin-bonded wheels after the three years mark when they are stored properly, you should always examine the wheels's appearance situation. Consider having older wheels inspected or speed-tested to determine if any degradation is present.

To prolong expiration date, store wheels in a dry, protected area free from extreme variations in temperature and far away from solvents. Establish a storage system that encourages you to use your oldest wheels first. And suggest not leave a wheel attached to a tool overnight.

Other Hebei Double Goats Grinding Wheel Manufacturing Co., Ltd products

METAL GRINDING WHEEL

Related Searches

- Sanding disc

- Surface treatment wheel

- Cylindrical grinding wheel

- Metal sanding disc

- Surfacing wheel

- Grinding sanding disc

- Flap disc

- Diamond-coated grinding wheel

- Aluminum sanding disc

- Cut-off wheel

- Flat grinding wheel

- Aluminum oxide sanding disc

- Finishing flap disc

- Polishing wheel

- Angle grinder grinding wheel

- Resin abrasive disc

- Aluminum oxide grinding wheel

- Deburring grinding wheel

- Dressing wheel

- Silicon carbide grinding wheel

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.