- Packing - Handling - Logistics

- Conveying

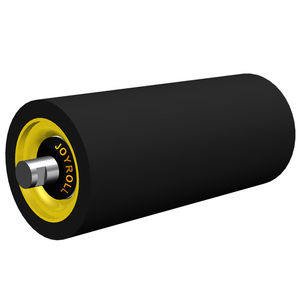

- Slip-on conveyor roller

- Hebei Joyroll Conveyor Machinery Co., Ltd.

Slip-on conveyor roller steelfor heavy loadslow-noise level

Add to favorites

Compare this product

Characteristics

- Drive mechanism

- slip-on

- Material

- steel

- Other characteristics

- for heavy loads, low-noise level, abrasion-resistant, high-performance, shock absorbing, durability, with steel ball bearing, lube-free, storage

- Diameter

Min.: 50 mm

(2 in)Max.: 219 mm

(9 in)- Length

Min.: 100 mm

(3.9 in)Max.: 2,400 mm

(94.5 in)- Max. load capacity

Min.: 13 kN

Max.: 62 kN

Description

Conveyor rollers are components of belt conveyor systems as they provide load support on carry side and return side.

SPECIFICATION:

Roller Diameter: 50, 60, 63.5, 76, 89, 102, 108, 114, 127, 133, 140, 152, 159, 165, 178, 194, 219mm

Roller Length: 100-2400mm.

Shaft Diameter: 20, 25, 30, 35, 40, 45, 50mm

Bearing type: 6204, 6205, 6305, 6206, 6306, 6307, 6308, 6309, 6310

Surface Treatment: Electrostatic Powder Coating, Galvanization.

Standard: DIN, CEMA, JIS, AS, SANS-SABS, GOST, AFNOR etc.

FEATURES

1. Low Total Indicator Run-out (T.I.R), low rotational resistance;

2. End cap to tube welds protected from rubber belt wear;

3. Highly-effective labyrinth seals protected from dust & water into the bearing;

4. Designed and manufactured for a long, trouble-free life;

5. Maintenance-free, high-quality sealed ball bearing.

APPLICATION

Mining

Steel mill

Cement plant

Power plant

Chemical Plant

Sea Port

Storage

etc.

CERTIFICATE

ISO9001, CE

Catalogs

No catalogs are available for this product.

See all of Hebei Joyroll Conveyor Machinery Co., Ltd.‘s catalogsOther Hebei Joyroll Conveyor Machinery Co., Ltd. products

Conveyor Roller

Related Searches

- Conveyor roller

- Metal conveyor roller

- Slip-on conveyor roller

- Steel conveyor roller

- Plastic conveyor roller

- Heavy load conveyor roller

- Abrasion-resistant conveyor roller

- High-performance conveyor roller

- Shock absorbing conveyor roller

- Durability conveyor roller

- Lube-free conveyor roller

- Polyethylene conveyor roller

- Storage conveyor roller

- Self-cleaning conveyor roller

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.