- Metrology - Laboratory

- Metrology and Test Equipment

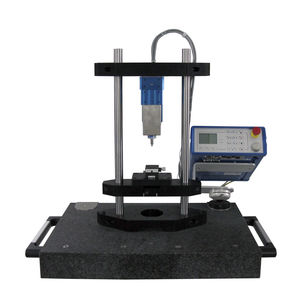

- Compression testing machine

- Hegewald & Peschke Meß- und Prüftechnik GmbH

- Products

- Catalogs

- News & Trends

- Exhibitions

Compression testing machine Inspekt S-L tensionfor automotive shaftsmechanical

Add to favorites

Compare this product

Characteristics

- Test type

- compression, tension

- Test material

- for automotive shafts

- Technology

- mechanical

Description

Universal shaft testing in the automotive industry

Universal testing machine inspekt S-L 250kN in horizontal configuration

Automotive universal shafts and drive trains are subject to considerable compressive and tensile mechanical loading during use.

The testing machine developed by Hegewald & Peschke MPT GmbH, with a maximum compressive and tensile test force of 250kN, is used in order to simulate the static loading of these vehicle components. The testing machine is able to test parts with lengths of up to 3000mm. The horizontal configuration of the Inspekt S-L 250kN enables the ergonomic changing of the universal shafts and testing under real vehicle installation conditions. Using the test software LabMaster, low frequency, cyclical loading and relief processes are realised with zero crossing.

This facilitates an examination of the hysteresis behaviour of the test specimen.

Catalogs

No catalogs are available for this product.

See all of Hegewald & Peschke Meß- und Prüftechnik GmbH‘s catalogsOther Hegewald & Peschke Meß- und Prüftechnik GmbH products

Universal Testing Machines

Related Searches

- Test machine

- Measuring device

- Test cabinet

- Measuring machine

- Test stand

- Indentation hardness tester

- Material testing machine

- Automatic test machine

- PC-controllable testing machine

- Temperature test cabinet

- Benchtop indentation hardness tester

- Compression test machine

- Digital hardness tester

- Vertical test machine

- Industrial test machine

- Universal test machine

- Automatic test stand

- Digital measuring device

- Thickness measuring machine

- Flexure testing machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.