- Metrology - Laboratory

- Metrology and Test Equipment

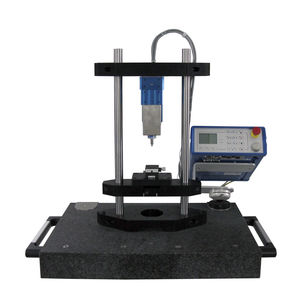

- Shearing resistance testing machine

- Hegewald & Peschke Meß- und Prüftechnik GmbH

- Products

- Catalogs

- News & Trends

- Exhibitions

Pressure testing machine inspekt S 50 kNcompressionuniversaltensile

Add to favorites

Compare this product

Characteristics

- Test type

- pressure, compression, universal, tensile, flexure, tension, tension and compression, static load, tensile strength, compression resistance, shearing resistance

- Operating mode

- computer-controlled

- Test material

- for metallic materials, for ceramic materials, for metallo-ceramic materials

- Sector

- for research and development

- Technology

- electromechanical

- Configuration

- vertical

- Other characteristics

- 4-column, high-temperature

Description

The high temperature testing system is based on the universal testing machine series inspekt. The inspekt S 50kN high-temperature testing machine from Hegewald & Peschke can be used to determine the mechanical properties of metallic and ceramic materials as well as metalloceramic composites. These are used, for example, as heat shields in space technology or as heat-insulating building materials.

The high-temperature test system has a high-temperature vacuum chamber for tests in the high-temperature range 1000°C-1800°C. The inert gas or vacuum chamber is used because many of the materials under investigation are sensitive to oxidation, such as refractory metals or carbon-bonded ceramics.

Precise strain measurement using a high-temperature extensometer in accuracy class 1 according to EN ISO 9513 is provided to record deformation up to the maximum temperature.

The spectrum of test methods ranges from tensile tests and compression tests to tests under 4-point bending load. Quasi-static tests, tests with repeated loads or partial unloadings as well as static creep tests up to 24 h are possible.

The high-temperature tests are controlled by the LabMaster materials testing software and the LabMaster module SteadyRise for heat treatments. The SteadyRise software is used to perform, monitor and document heat treatment processes. The temperature controllers are connected directly to the software via the hardware interface supplied.

The complete high-temperature solution from Hegewald & Peschke ensures reliable and traceable test results thanks to the accurate temperature control, ease of use and user-friendly test software.

Catalogs

No catalogs are available for this product.

See all of Hegewald & Peschke Meß- und Prüftechnik GmbH‘s catalogsOther Hegewald & Peschke Meß- und Prüftechnik GmbH products

Universal Testing Machines

Related Searches

- Test machine

- Measuring device

- Test cabinet

- Measuring machine

- Test stand

- Indentation hardness tester

- Material testing machine

- Automatic test machine

- PC-controllable testing machine

- Temperature test cabinet

- Benchtop indentation hardness tester

- Compression test machine

- Digital hardness tester

- Vertical test machine

- Industrial test machine

- Universal test machine

- Automatic test stand

- Digital measuring device

- Thickness measuring machine

- Flexure testing machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.