- Metrology - Laboratory

- Metrology and Test Equipment

- Universal testing machine

- Hegewald & Peschke Meß- und Prüftechnik GmbH

- Products

- Catalogs

- News & Trends

- Exhibitions

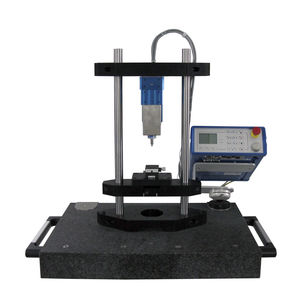

Universal testing machine inspekt blueautomaticfor electronic componentsfor the electronics industry

Add to favorites

Compare this product

Characteristics

- Test type

- universal

- Operating mode

- automatic

- Test material

- for electronic components

- Sector

- for the electronics industry

- Technology

- electromechanical, digital

- Configuration

- vertical

- Other characteristics

- double-column

Description

Universal testing machines for testing electronic components and parts.

For testing fasteners, the testing machine can be equipped with grips and a T-slot plate for flexible positioning and axial alignment of the specimen. An integrated digital multimeter is used to measure resistance during tensile strength testing.

In another test setup, a shear fixture can be used to test contact elements, such as switching contacts of circuit breakers from the electrical industry, to ensure safety when handling electrical components. The shear tests are used to determine whether the soldered contacts between the switching contact and the component can withstand the stresses in practice. For this purpose, the component to be tested is clamped in a specially developed shear fixture and subjected to a steadily increasing shear force until the switching contact shears off.

For the testing of electrical switches and pushbuttons, special devices are used to check the force and the distance required to actuate and release the pushbuttons or to operate the switches.

If necessary, several different load cells can be mounted simultaneously to apply different force ranges.

The force is checked via these load cells or via the voltage of a probe adapted to them.

Test leads for the switching signal are connected to the switch/pushbutton so that there is immediate feedback of the signal in connection with the test process.

Catalogs

Other Hegewald & Peschke Meß- und Prüftechnik GmbH products

Universal Testing Machines

Related Searches

- Test machine

- Measuring device

- Test cabinet

- Measuring machine

- Test stand

- Indentation hardness tester

- Material testing machine

- Automatic test machine

- PC-controllable testing machine

- Temperature test cabinet

- Benchtop indentation hardness tester

- Compression test machine

- Digital hardness tester

- Vertical test machine

- Industrial test machine

- Universal test machine

- Automatic test stand

- Digital measuring device

- Thickness measuring machine

- Flexure testing machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.