- Metrology - Laboratory

- Metrology and Test Equipment

- Multi-parameter testing machine

- Hegewald & Peschke Meß- und Prüftechnik GmbH

- Products

- Catalogs

- News & Trends

- Exhibitions

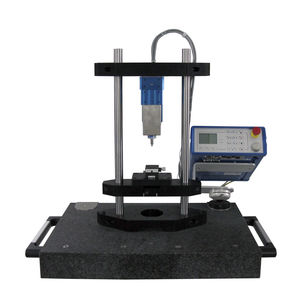

Universal testing machine Inspekt H-HFmulti-parameterfor materialshydraulic

Add to favorites

Compare this product

Characteristics

- Test type

- universal, multi-parameter

- Test material

- for materials

- Technology

- hydraulic

Description

Universal testing machines inspekt H-HF

Servo-hydraulic material testing machines up to 1000kN

The servo-hydraulic universal testing machines of the series inspekt H-HF have been designed for routine jobs in metalworking and building materials industries. They are equipped with a mechanical wedge type grip for round and flat specimens. Furthermore, two test spaces allow for tensile, pressure, and bending tests without changeover times, which guarantees a high test throughput. If required, it is also possible to use a load frame with a user-friendly, hydraulic clamping tool.

Load frame

The lower crosshead of the load frame is guided with the help of two fixed spindles, which are connected to the machine base. An electric motor moves the crosshead to the necessary distance to the upper crosshead. The upper crosshead is connected to the machine bench with two load-bearing columns. The machine bench is attached to the piston of the hydraulic cylinder. Thus, the machine bench is transmitting load to the upper crosshead.

Furthermore, the oil pump responsible for the hydraulics is equipped with a limiting switch, which stops every movement automatically when the crossheads get too close to each other. In total, the hydraulics unit consists of the oil pump, an oil tank, a filter, one hydraulic and one electro-hydraulic servo valve. This whole unit is stored in the lower part of the control cabinet.

Load measurement

To ensure exact load measurement, Hegewald & Peschke MPT GmbH has equipped its universal testing machines of the series inspekt-H with a pressure sensor in the hydraulic circuit. It contains special electronic measuring equipment.

Catalogs

No catalogs are available for this product.

See all of Hegewald & Peschke Meß- und Prüftechnik GmbH‘s catalogsOther Hegewald & Peschke Meß- und Prüftechnik GmbH products

Universal Testing Machines

Related Searches

- Test machine

- Measuring device

- Test cabinet

- Measuring machine

- Test stand

- Indentation hardness tester

- Material testing machine

- Automatic test machine

- PC-controllable testing machine

- Temperature test cabinet

- Benchtop indentation hardness tester

- Compression test machine

- Digital hardness tester

- Vertical test machine

- Industrial test machine

- Universal test machine

- Automatic test stand

- Digital measuring device

- Thickness measuring machine

- Flexure testing machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.