- Metrology - Laboratory

- Metrology and Test Equipment

- Rockwell hardness tester

- Hegewald & Peschke Meß- und Prüftechnik GmbH

- Products

- Catalogs

- News & Trends

- Exhibitions

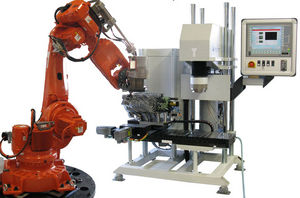

Rockwell hardness tester floor-mountedfor crankshaftsautomatic

Add to favorites

Compare this product

Characteristics

- Type

- Rockwell

- Mounting

- floor-mounted

- Product applications

- for crankshafts

- Other characteristics

- automatic

Description

The hardness testing systems are automated and/or integrated into the production process, with and without component feed.

Hardness tests on components with complicated geometries or tests in the running production can sometimes not be covered with standard hardness testers. In these cases the company Hegewald & Peschke GmbH offers you the complete engineering know-how for the realization of the testing task. Our already produced hardness testing systems include: Hardness testing stations for crankshafts, automatic rim hardness testing systems, hot hardness testing systems, circular blank testing systems and portal hardness testing systems.

Rockwell Hardness Test Bench for crankshafts

Automatic Hardness Testing on crankshafts

All controls for setting up the machine and for the electronic positioning and test gripper clamping are placed in an operator panel in front of the machine. Through a serial interface at the hardness test head, measured values can easily be sent to a data capture device (printer, pc).

The crankshaft will be transported to the hardness test bench using a suitable hoist (hoist and separate lifting accessories are not included in delivery) and will be placed and clamped between spikes.

To realise this, the clamp table has to be driven to its open cut load position.

The crankshaft can be rotated to its axis and manual freely positioned m below the test head. If the machine has reached its testing position, the user is operating the electromechanic / -pneumatic bracing and centering.

Catalogs

No catalogs are available for this product.

See all of Hegewald & Peschke Meß- und Prüftechnik GmbH‘s catalogsOther Hegewald & Peschke Meß- und Prüftechnik GmbH products

Hardness Testers

Related Searches

- Test machine

- Measuring device

- Test cabinet

- Measuring machine

- Test stand

- Indentation hardness tester

- Material testing machine

- Automatic test machine

- PC-controllable testing machine

- Temperature test cabinet

- Compression test machine

- Benchtop indentation hardness tester

- Digital hardness tester

- Vertical test machine

- Automatic test stand

- Industrial test machine

- Universal test machine

- Digital measuring device

- Tensile test machine

- Flexure testing machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.