- Industrial machines and equipment

- Printing, Marking and Engraving

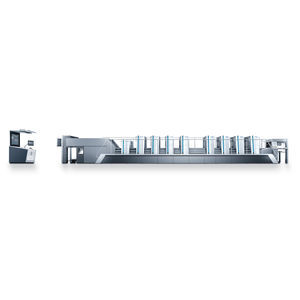

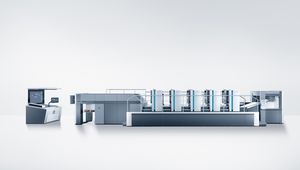

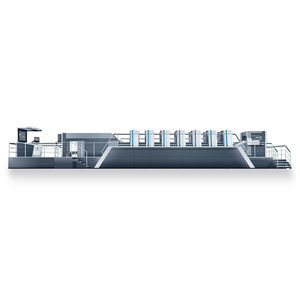

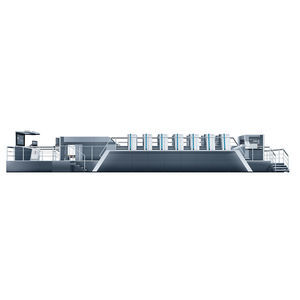

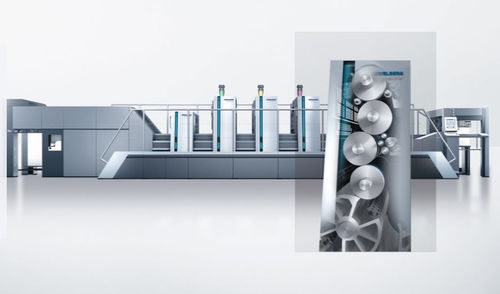

- Sheet fed offset press

- Heidelberger Druckmaschinen AG

Sheet fed offset press Speedmaster XL 75 Anicolor 2for paper

Add to favorites

Compare this product

Characteristics

- Type of printing

- Sheet fed

- Other caracteristics

- for paper

Description

The Speedmaster XL 75 with Anicolor 2 zoneless short inking unit is designed to guarantee you high productivity, especially with short runs – for fast and cost-effective production in 100 percent offset quality.

The Anicolor 2 technology

The inking unit of the Speedmaster XL 75 Anicolor 2 consists of a single-speed screen roller with ink chamber blade. The ink is transferred from the screen roller to the printing plate by an ink form roller. The ink density can be markedly changed and adapted to a wide range of substrates and spot colors by adapting the temperature and activating the Anicolor booster.

Economical even with short production runs

Even short production runs can be economically produced with the Speedmaster XL 75 Anicolor 2. The fast and constant inking means that print jobs are ready for production after just a few sheets. With longer runs, you benefit from the advantages of the offset technology.

At a glance

• Cost-effective production of very short runs

• Shortest makeready times

• Cost savings thanks to least possible paper waste

• High standardization and automation of the printing process

• Fast, uniform inking and high production stability

• Wide variety of substrates

• Printing of spot colors, metallic colors, and UV or special coatings

Suitable for the following segments

One of the main areas of application of Anicolor 2 is commercial printing , where the Anicolor technology provides the optimal solution for fast and economical printing of very short runs.

In label and packaging printing (e.g. in the pharmaceutical or cosmetic industry), Anicolor 2 opens up huge savings potential for very short production runs.

Catalogs

Other Heidelberger Druckmaschinen AG products

Offset printing

Related Searches

- Flexographic press

- Hot foil stamping machine

- Offset printing machine

- In-line flexographic press

- Paper flexographic press

- Sheet fed offset printing machine

- 8-color flexographic press

- Paper trimmer

- Paper offset press

- 6-color flexographic press

- Packaging flexographic press

- Medium-sized offset press

- 4-color flexographic press

- Automatic paper cutter

- Programmable paper cutter

- Plate processor

- Web-fed offset press

- High-speed paper cutter

- Carton flexographic press

- Ctp plate

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.