- Industrial machines and equipment

- Printing, Marking and Engraving

- Thermal CtP

- Heidelberger Druckmaschinen AG

Thermal CtP Suprasetter A106manual

Add to favorites

Compare this product

Characteristics

- Type

- thermal

- Loading

- manual

- Plate width

Max.: 1,140 mm

(45 in)Min.: 323 mm

(13 in)- Plate length

Max.: 930 mm

(37 in)Min.: 370 mm

(15 in)

Description

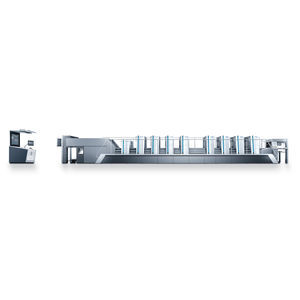

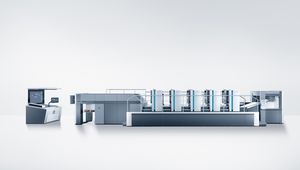

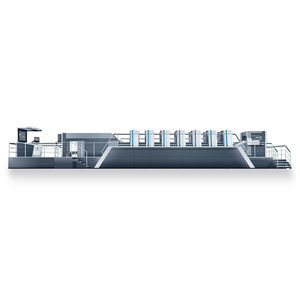

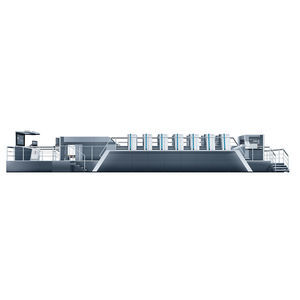

The modular design of the Suprasetter A106/106 provides you with maximum flexibility for the medium-size format range. Their Intelligent Diode System (IDS) virtually eliminates production losses. An integrated cooling system prevents any adverse impact from external temperatures.

Fully automatic plate production

The platesetters are available in a variety of arrangements: the basic model can be expanded with a Dual Cassette Loader for fully automatic operation with plate cassettes. The Auto Pallet Loader, which loads printing plates straight from a transport pallet, is the ultimate in efficiency. And the automated loading systems can be combined if you need to process different plate formats and types.

For top-level productivity, the platesetters can also be integrated into the fully automated plate production lines. This means that all sequences such as loading, imaging, punching, developing, beveling and job-dependent unloading can be carried out continuously around the clock without manual intervention. You can adapt your plate requirements at any time.

At a glance

• Flexible equipment – from manual to fully automatic Suprasetter

• Smart Plate Handling

• With integrated temperature stabilization, punching, suction, and dust filter systems

Catalogs

No catalogs are available for this product.

See all of Heidelberger Druckmaschinen AG‘s catalogsOther Heidelberger Druckmaschinen AG products

Offset printing

Related Searches

- Flexographic press

- Hot foil stamping machine

- Offset printing machine

- In-line flexographic press

- Paper flexographic press

- Sheet fed offset printing machine

- 8-color flexographic press

- Paper trimmer

- Paper offset press

- 6-color flexographic press

- Packaging flexographic press

- Medium-sized offset press

- 4-color flexographic press

- Automatic paper cutter

- Programmable paper cutter

- Plate processor

- Web-fed offset printing machine

- High-speed paper cutter

- Carton flexographic press

- Ctp plate

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.