- Production Machines

- Other Manufacturing Equipment

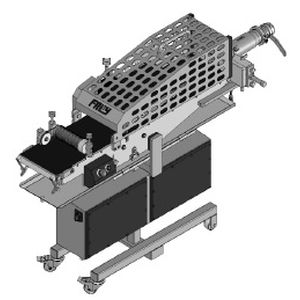

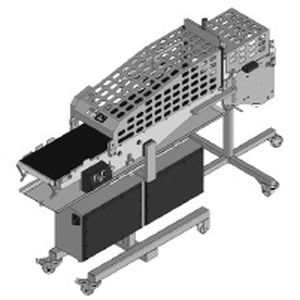

- Croquette production line

- Heinrich Frey Maschinenbau GmbH

Croquette production line

Add to favorites

Compare this product

Characteristics

- Finished product

- croquette

Description

The Cevapcici-Line is an optimal production line for manufacturing cevapcici, mici, croquettes and other similar formed food.

Exemplarily we show you the setup of a Cevapcici-Line, built with our Convenience Food modules.

The start of all is the vacuum filling machine, sizes F-LINE F60 and above.

With the filling machine the meat is processed without any air and pumped to the filling head.

The filling head CL 6 divides the meat flow into 6 uniform meat strings. These are deposited on the portioning conveyor belt.

Six strings are fed into the cutting device SE 25 by the portioning belt PB 30/36. They are cut in portions, depending on the settings in the control unit of the filling machine. Optionally the portioning belt can be equiped with a product spraying with water or oil (WI). Additionally an appliance of the portioning belt can be used to provide paper to preprocess the packaging. After passing the cutting device, the product is lead to the universal transporting conveyor belt.

The speed of the universal transporting conveyor belt UTB 30/135 can be varied to produce gaps between the products. These gaps can be synchronous to e.g. the packaging process. Optionally the universal transporting conveyor belt can be set up with a watered scraper and a collecting tray with drain (AA 135).

Catalogs

No catalogs are available for this product.

See all of Heinrich Frey Maschinenbau GmbH‘s catalogsOther Heinrich Frey Maschinenbau GmbH products

Convenience Food Lines and Modules

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.